Effectiveness analysis of thermal design methods for a 12.5 kW Hall thruster

-

摘要: 为了对取消散热板后的12.5 kW霍尔推力器的热设计优化提供工程指引,本文计算了推力器热耗并校准了热模型,之后采用有限元仿真结合热平衡试验验证对12.5 kW霍尔推力器的不同热设计措施的有效性进行了分析。结果显示,在取消散热板后,推力器各部件平均温升达到50~150 ℃,在考虑推力器主要的热量传递路径后,提出6种热设计措施并分别进行仿真分析。分析结果表明,措施4和措施6,即阻断空心阴极与内线圈的辐射热交换以及提高导磁底座外磁屏和外线圈套筒的发射系数,对控制内线圈及导磁底座的温升具有显著影响。其次,基于措施1即阻断内线圈和导磁底座之间的热传导,在二者间增加了厚度为5 mm隔热垫并开展了热平衡试验验证。结果显示,各部件的仿真值与实测值的比对误差均小于10%,而导磁底座和外壳处的温度比对误差最大,这是由于试验中仍存在轴向热传导所导致。比对结果验证了针对措施1所开展仿真分析的准确性,同时也间接证明了措施4组合措施6的降温效果有效性。Abstract:

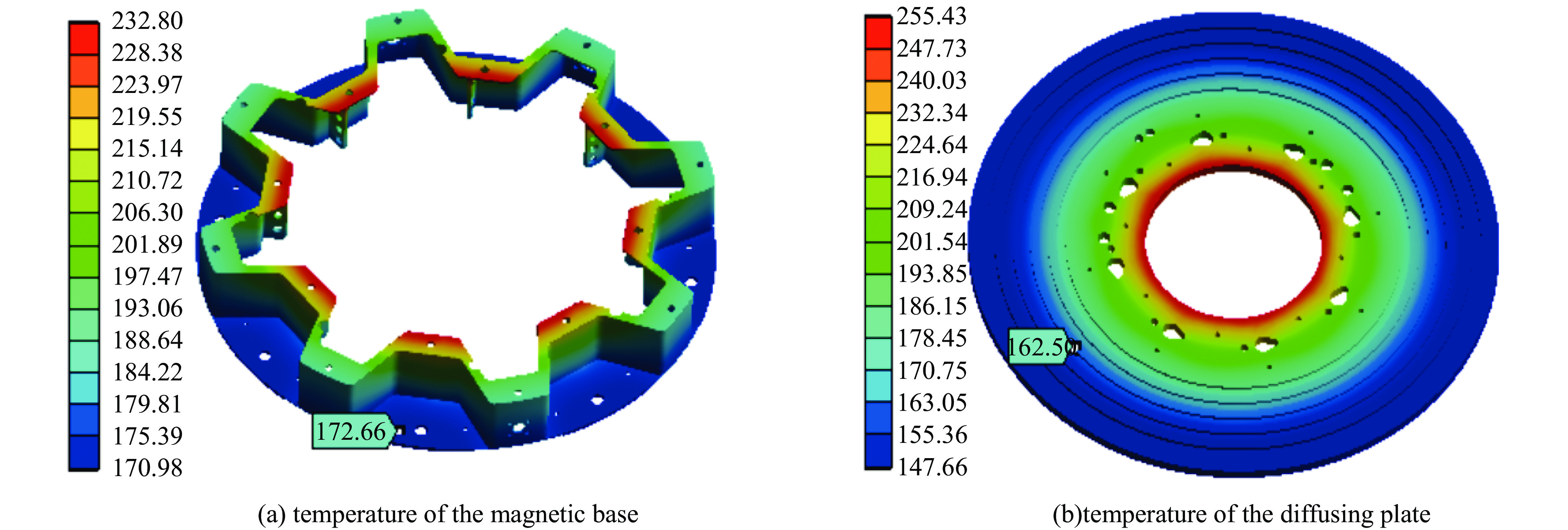

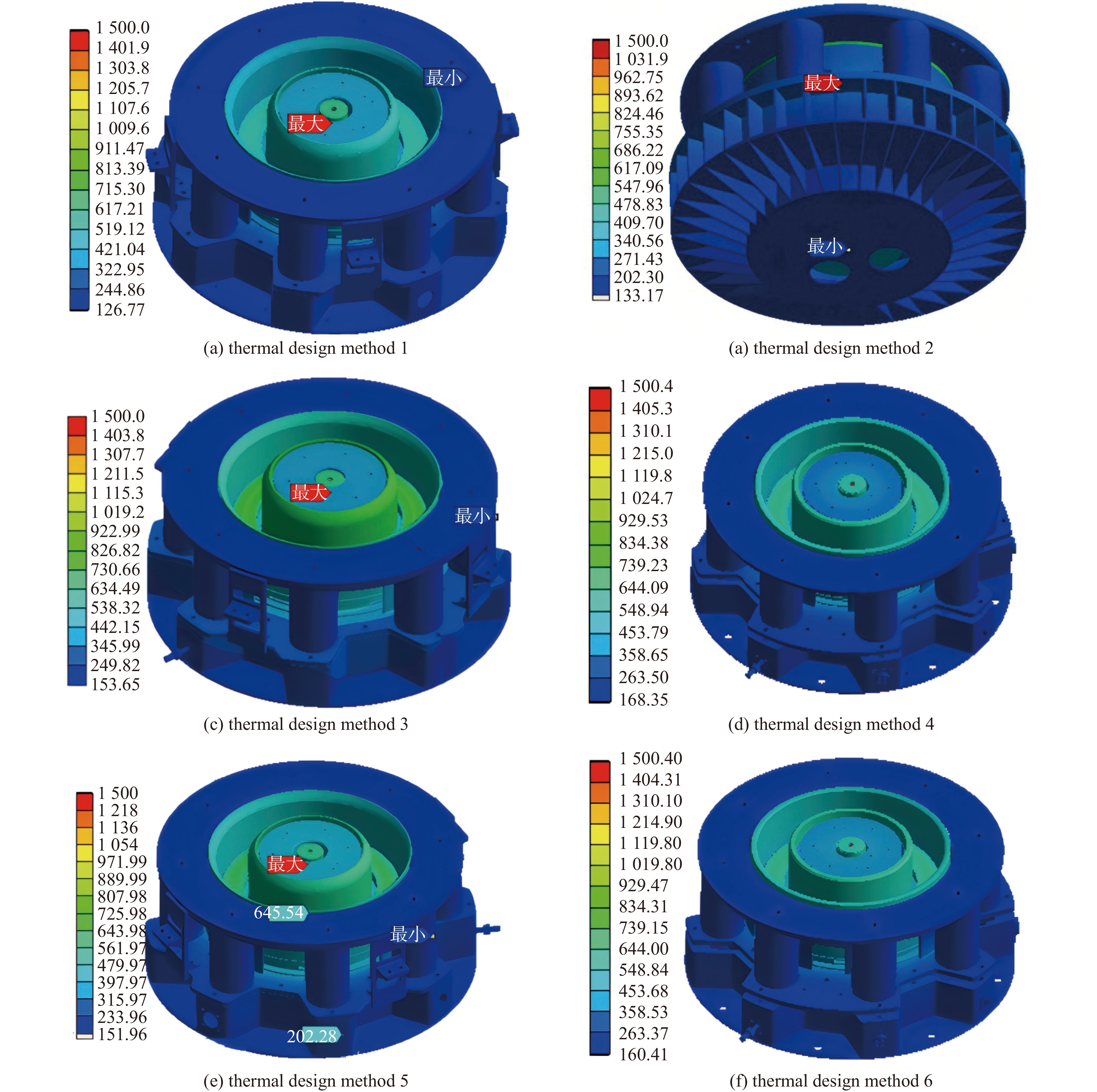

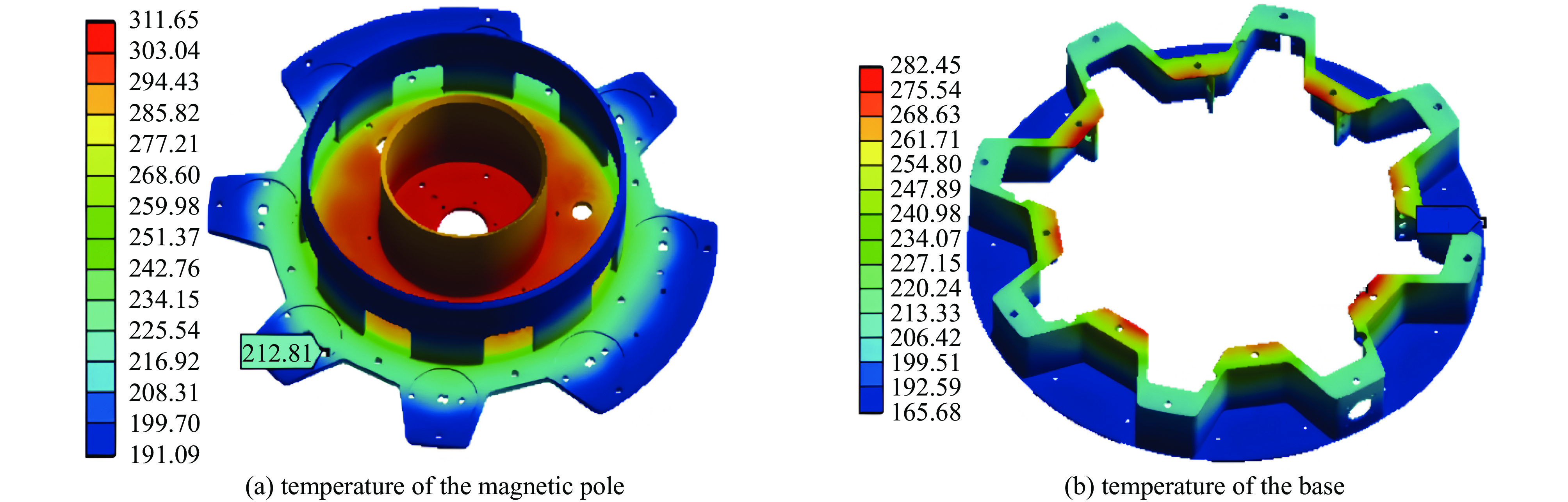

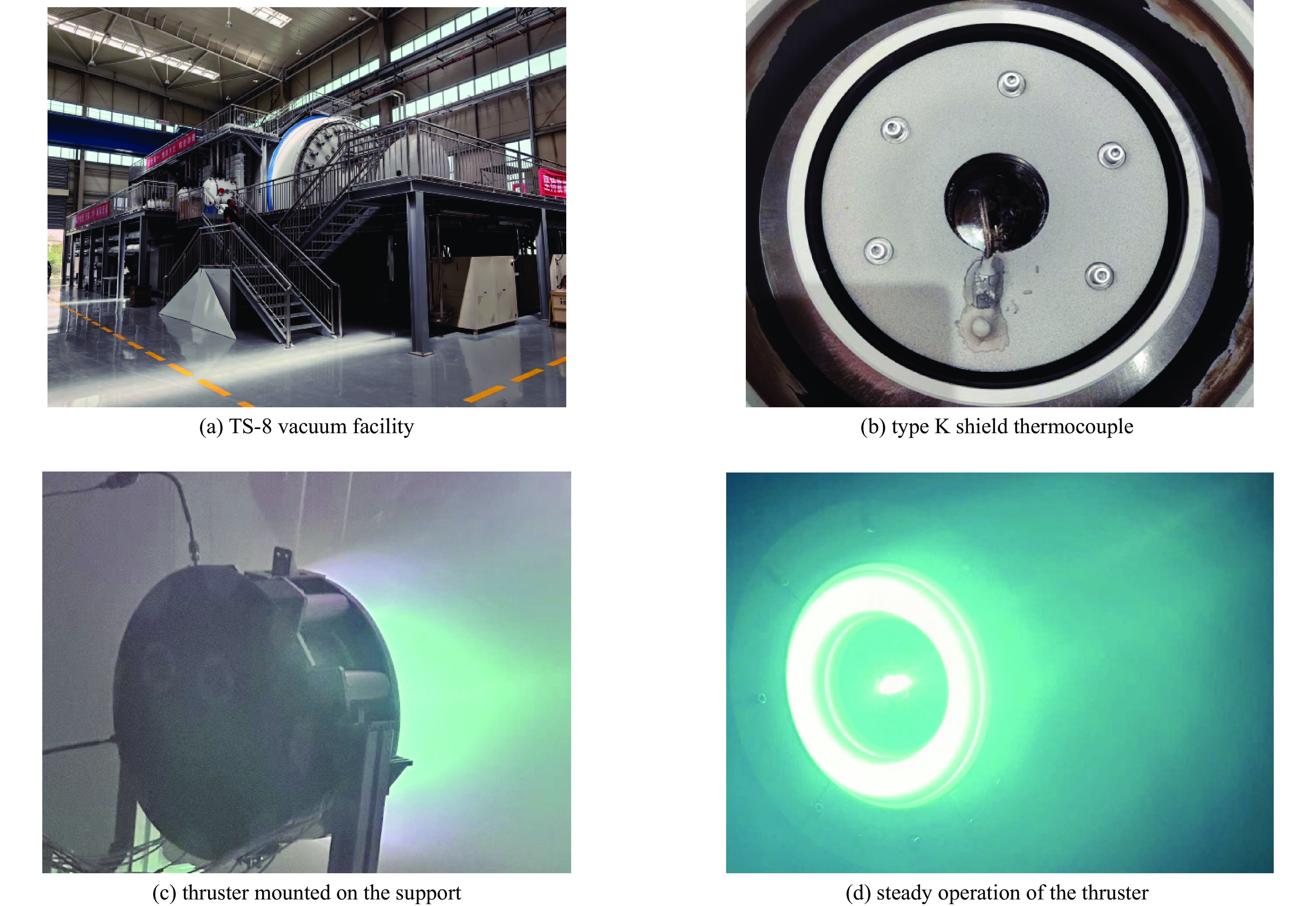

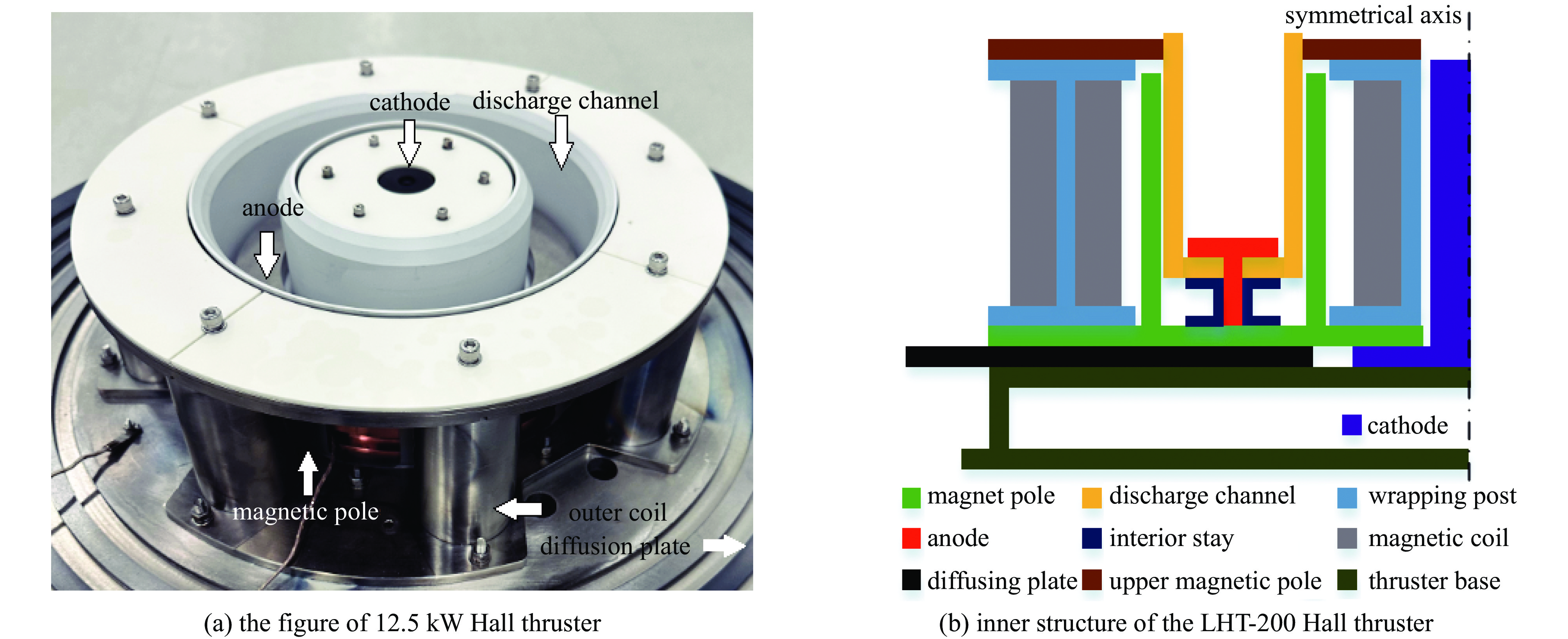

Background As the working power of Hall thrusters increases, the overall temperature of the thrusters will rise accordingly. A significant increase in temperature can lead to a decline in work performance and structural failure of the thruster. Therefore, a reasonable thermal design can significantly enhance the performance stability and reliability of Hall thrusters.Purpose The purpose of this paper is to provide engineering guidance for the reasonable thermal design of a 12.5 kW Hall thruster without the cooling plate. In addition, a thermal model of the thruster is established and verified for the continuous optimization of the thruster’s structure.Methods The heat loss distribution of the 12.5 kW Hall thruster is calculated by theoretical analysis, then FEM (finite element method) is used to bulid the thermal model of a 12.5 kW Hall thruster, and six different thermal design methods are proposed in this paper. In addition, the effectiveness of different thermal design method is analyzed by finite element simulation combined with a thermal balance experiment.Results The results show that the average temperature rise of each thruster part reaches 50~150 ℃ after the cooling plate is removed. Therefore, considering the main heat transfer path of thruster, six thermal design methods are proposed and simulated, respectively. The results indicate that the method 4 and the method 6, namely, intercept the radiation heat exchange between the hollow cathode and the inner coil, and increasing the emission coefficient of outer magnetic screen and the outer coil sleeve. Meanwhile, Based on the method 1, that is, blocking the heat conduction between the inner coil and the magnetic base, then a thickness of 5 mm heat insulation pad is added between the inner coil and the magnetic base. The test results show that the comparison errors between the simulations and the measurements of each component are less than 10%, and the comparison error between the magnetic base and the thruster base is the largest, which is caused by the top-down axial heat conduction in the test.Conclusions Axial heat conduction and radial heat radiation are the main heat transfer methods of the Hall thruster. According to the research results, the combination of the method 4 and 6 is the most effective way for thermal design optimization. Subsequently, the process wull be verified to achieve the purpose of significantly reducing the temperature of the thruster.-

Key words:

- Hall thruster /

- Thermal boundaries /

- Thermal design /

- Heat transfer

-

表 1 12.5kW额定工况下的热耗设置

Table 1. Setting of heat loss under 12.5kW condition

heat loss applied region heat loss /W inner wall of the channel 900 outer wall of the channel 1110 anode surface 549 inner coil 71.3 outer coil 120.8 cathode keeper 9.24 total heat loss 2760.34 表 2 推力器关键部件表面的发射系数设置

Table 2. Setting of emission coefficient on the surface of key components

components material emissivity radiation relationship upper magnetic pole DT-4C 0.45 surface-space outer coil DT-4C 0.45 surface-space magnetic base TC-4 0.50 surface-space diffusion plate 2A12 0.85 surface-space thruster mounting base 2A12 0.75 surface-space inner and outer wall of channel BN 0.80 surface-sueface cathode tube-heat shield Ta 0.40 surface-sueface heat shield-keeper Ta 0.40 surface-sueface 表 3 初始结构下霍尔推力器的热仿真以及实测结果比对(单位:℃)

Table 3. Comparison of the simulations and experiments of original structure of the Hall thruster (unit: ℃)

components measurements (with diffusion plate) simulations (with diffusion plate) simulations (without diffusion plate) upper magnetic pole 192 188~194 355 inner wrapping post 318 313~319 365 magnetic base 208 205~212 316 diffusion plate 157 160~166 — thruster base 159 165~169 233 interior stay 304 301~307 383 表 4 不同热设计措施下核心部件的温度仿真结果(单位:℃)

Table 4. Temperature simulation results of key components under different thermal design method (unit: ℃)

components original method 1 method 2 method 3 method 4 method 5 method 6 inner coil 365 371 357 270 238 359 331 discharge channel 581 527 535 526 524 541 529 magnetic base 316 268 279 265 261 320 303 thruster base 233 143 138 158 208 202 171 interior stay 383 296 375 293 290 344 334 anode 492 455 448 453 451 489 486 表 5 结合措施4和措施6后的核心部件温度分布(单位:℃)

Table 5. Temperature distribution of key components under method 4 combined with method 6 (unit: ℃)

components with diffusion plate without diffusion plate method 4 method 6 method (4+6) inner coil 318 365 238 331 295 magnetic base 208 316 261 303 213 thruster base 159 233 208 171 167 interior stay 304 383 290 334 311 aniode 412 492 451 486 447 表 6 基于热设计措施1的各关键部件的温度比对(单位:℃)

Table 6. Temperature comparison of key components under thermal design method 1 (unit: ℃)

components simulations measurements errors inner coil 371 353 5.1% discharge channel 527 512 2.9% magnetic base 268 289 7.3% thruster base 143 157 8.9% interior stay 296 292 1.4% aniode 455 436 4.4% -

[1] 康小录, 张岩, 刘佳, 等. 大功率霍尔电推进研究现状与关键技术[J]. 推进技术, 2019, 40(1):1-11Kang Xiaolu, Zhang Yan, Liu Jia, et al. Research status and key technologies of high-power hall electric propulsion[J]. Journal of Propulsion Technology, 2019, 40(1): 1-11 [2] 耿海, 吴辰宸, 孙新锋, 等. 高功率空间电推进技术发展研究[J]. 真空与低温, 2022, 28(1):14-25Geng Hai, Wu Chenchen, Sun Xinfeng, et al. The high power space electric propulsion technology[J]. Vacuum and Cryogenics, 2022, 28(1): 14-25 [3] Casaregola C, Pergola P, Ruggiero A. Future scenarios for space transportation and exploration based on high power electric propulsion technologies[C]//Proceedings of the 47th AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit. 2011. [4] Andreussi T, Giannetti V, Leporini A, et al. Influence of the magnetic field configuration on the plasma flow in hall thrusters[J]. Plasma Physics and Controlled Fusion, 2018, 60: 014015. doi: 10.1088/1361-6587/aa8c4d [5] Dorf L, Raitses Y, Fisch NJ. Effect of magnetic field profile on the anode fall in a hall-effect thruster discharge[J]. Physics of Plasmas, 2006, 13: 057104. doi: 10.1063/1.2174825 [6] Archipov A, Krochak Z, Maslennikov Y. Thermal design of the electric propulsion system components - numerical analysis and testing at Fakel[C]//Proceedings of the 34th AIAA/ASME/SAE/ASEE Joint Propulsion Conference and Exhibit. 1998. [7] 陈笃华, 王平阳, 王尚, 等. 50kW级高功率霍尔推力器放电通道数值模拟研究[J]. 上海航天(中英文), 2021, 38(6):78-84Chen Duhua, Wang Pingyang, Wang Shang, et al. Numerical simulation of the discharge channel of a 50 kW high-power hall thruster[J]. Aerospace Shanghai (Chinese & English), 2021, 38(6): 78-84 [8] Hani K, Thomas H, Wen S H, et al. Performance and thermal characterization of a 20 kW class long life Hall thruster[R]. IEPC-2013-136. [9] Kamhawi H, Liu T M, Benavides G F, et al. Performance, stability, and thermal characterization of a sub-kilowatt Hall thruster[C]//Proceedings of the 36th International Electric Propulsion Conference. 2019: 1-20. [10] Mao W, Shen Y, Hu Y L, et al. Investigation of thermal characteristics in a 1.35 kW magnetic focus type Hall thruster (HEP-100MF)[R]. IEPC-2015-214. [11] Myers J L, Kamhaw H, Yim J, et al. Hall thruster thermal modeling and test data correlation[C]//Proceedings of the 52nd AIAA/SAE/ASEE Joint Propulsion Conference. 2016. [12] 赵震, 程佳兵, 康小录. 温度对磁屏蔽霍尔推力器磁场构型的影响研究[J]. 中国空间科学技术, 2020, 40(4):29-37Zhao Zhen, Cheng Jiabing, Kang Xiaolu. Effect of temperature on magnetic field configuration of magnetically shielded Hall thruster[J]. Chinese Space Science and Technology, 2020, 40(4): 29-37 [13] 苗鹏, 于博, 康小录, 等. 嵌套霍尔推力器的热优化策略研究[J]. 推进技术, 2024, 45:2304031Miao Peng, Yu Bo, Kang Xiaolu, et al. An investigation of thermal optimization strategies in nested Hall thrusters[J]. Journal of Propulsion Technology, 2024, 45: 2304031 [14] 刘星宇, 李鸿, 毛威, 等. 霍尔推力器能量损失系统性评价方法[J]. 推进技术, 2022, 43:200868Liu Xingyu, Li Hong, Mao Wei, et al. Systematic evaluation method for power loss of hall thruster[J]. Journal of Propulsion Technology, 2022, 43: 200868 [15] 徐凡, 王磊, 丁永杰, 等. 永磁霍尔推力器性能退化及寿命评估研究[J]. 推进技术, 2023, 44:2212024Xu Fan, Wang Lei, Ding Yongjie, et al. Performance degradation and life assessment of permanent magnet hall thruster[J]. Journal of Propulsion Technology, 2023, 44: 2212024 [16] 陈龙, 阚子晨, 杨叶慧, 等. 霍尔推力器磁屏蔽磁场设计及通道结构优化仿真研究[J]. 推进技术, 2023, 44:2208107Chen Long, Kan Zichen, Yang Yehui, et al. Simulation study on magnetic shielding field design and channel structure optimization of hall thruster[J]. Journal of Propulsion Technology, 2023, 44: 2208107 [17] Ding Y J, Li H, Li P, et al. Effect of relative position between cathode and magnetic separatrix on the discharge characteristic of Hall thrusters[J]. Vacuum, 2018, 154: 167-173. doi: 10.1016/j.vacuum.2018.05.005 [18] Hofer R R, Johnson L K, Goebel D M, et al. Effects of internally mounted cathodes on Hall thruster plume properties[J]. IEEE Transactions on Plasma Science, 2008, 36(5): 2004-2014. doi: 10.1109/TPS.2008.2000962 [19] Goebel D, Katz I. JPL space science and technology series[M]//Goebel D M, Katz I. Fundamentals of Electric Propulsion: Ion and Hall Thrusters. Hoboken: John Wiley & Sons, Inc. , 2008: 357-363. [20] Sun M M, Geng H, Liu C, et al. Simulation and measurement of plume characteristics of a hall thruster with 12.5 kW[J]. Journal of Aerospace Technology and Management, 2025, 17: e1325. doi: 10.1590/jatm.v17.1373 [21] 孙明明, 顾左, 郭宁, 等. 离子推力器空心阴极热特性模拟分析[J]. 强激光与粒子束, 2010, 22(5):1149-1152 doi: 10.3788/HPLPB20102205.1149Sun Mingming, Gu Zuo, Guo Ning, et al. Thermal analysis of hollow cathodes for ion thruster[J]. High Power Laser and Particle Beams, 2010, 22(5): 1149-1152 doi: 10.3788/HPLPB20102205.1149 [22] 杜林颖, 于鸿彬, 王磊. 基于K型热电偶温度传感器的测温系统研究[J]. 现代电子技术, 2019, 42(14):36-40Du Linying, Yu Hongbin, Wang Lei. Research on temperature measurement system based on K-type thermocouple temperature sensor[J]. Modern Electronics Technique, 2019, 42(14): 36-40 -

下载:

下载: