In-situ characterization of metal laser additive manufacturing using a laser-driven X-ray source

-

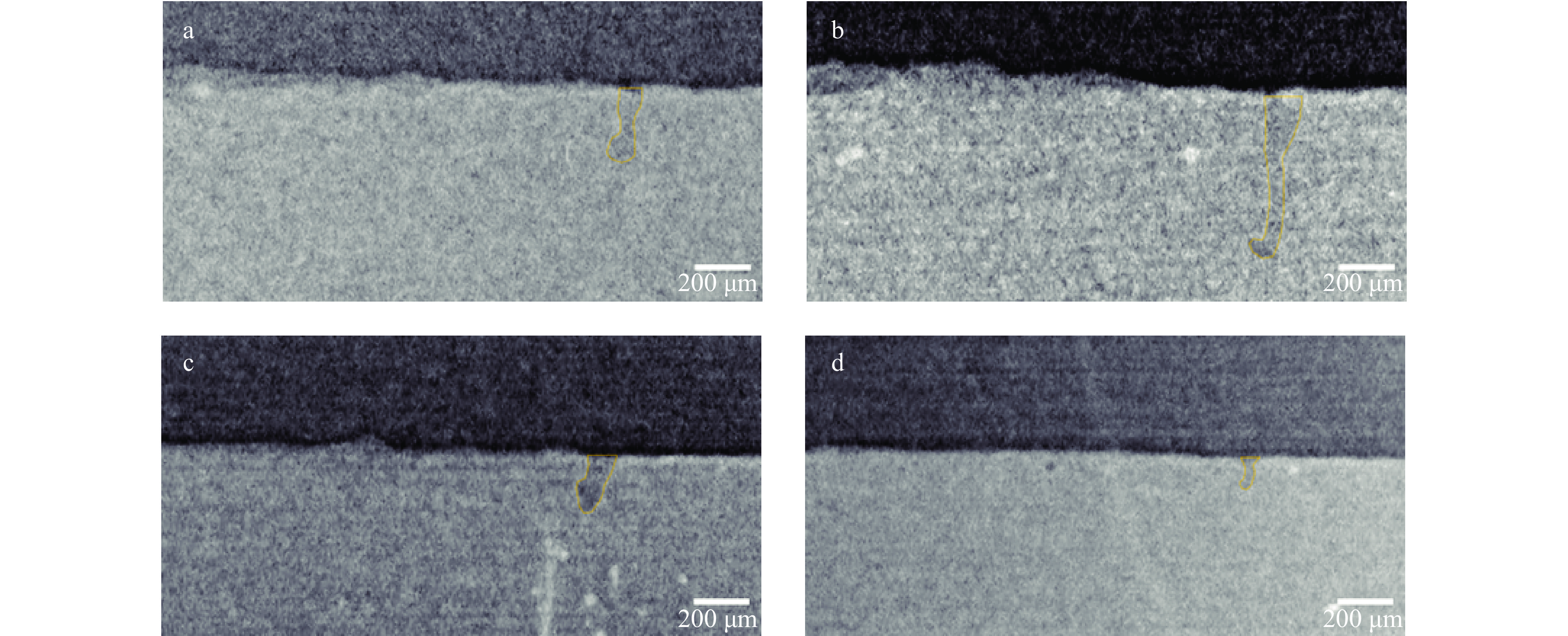

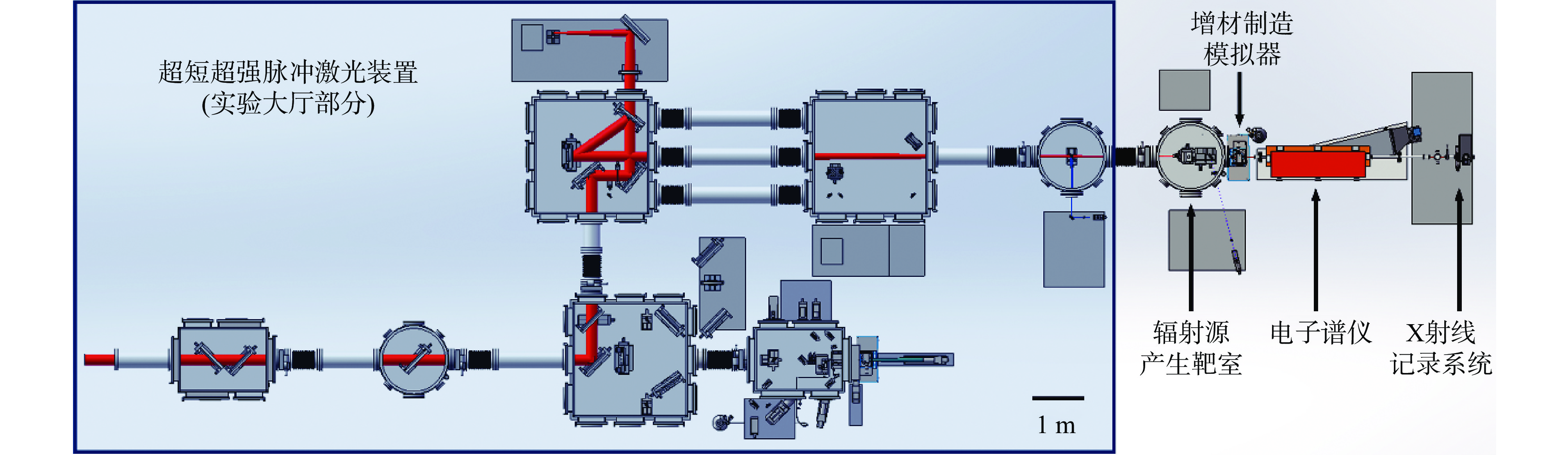

摘要: 金属激光增材制造中的孔洞缺陷通常起源于熔池内部,并呈现出微观且高度动态的演化特性。采用高时空分辨的X射线透视成像技术,可对缺陷的产生与演化过程进行原位观测,对于揭示缺陷形成机理和优化工艺参数具有重要意义。本研究基于超强超短脉冲激光驱动的Betatron辐射源,发展了面向金属激光增材制造的高时空分辨X射线透视成像技术,并开展了不同工艺参数下微熔池的原位表征研究。结果表明,利用Betatron辐射源可实现对百微米厚度金属样品中熔池及匙孔动态结构的透视成像,空间分辨率达到4 μm。该研究为激光驱动X射线辐射源在金属激光增材制造中缺陷形成机理及工艺优化方面的应用奠定了重要基础。

-

关键词:

- 金属激光增材制造 /

- Betatron辐射源 /

- 超快微焦点X射线照相 /

- 原位表征 /

- 匙孔

Abstract: Pore defects in metal laser additive manufacturing (AM) typically originate and evolve within the melt pool, exhibiting microscopic and highly transient characteristics. High spatiotemporal resolution X-ray imaging provides a powerful tool for in situ characterization of these processes, which is essential for understanding defect formation mechanisms and optimizing processing parameters. In this study, a high spatiotemporal resolution X-ray imaging technique tailored for metal laser AM was developed utilizing Betatron radiation generated by ultra-intense, ultrashort pulsed lasers. This technique was employed to perform in-situ characterization of micro-melt pools under various processing conditions. The results show that the Betatron X-ray source allows real-time imaging of melt pool and keyhole dynamic in metal samples with thicknesses on the order of hundreds of micrometers, achieving a spatial resolution of 4 μm. These findings provide a solid foundation for the future application of laser-driven X-ray sources in investigating defect formation mechanisms and advancing process optimization in metal laser AM. -

表 1 不同加工参数下的熔池匙孔特征实验结果

Table 1. Experimental results of keyhole characteristics in melt pools under different processing parameters

No. laser power/W scan speed/(mm/s) keyhole width/μm keyhole depth/μm P1 450 600 87.4 267.8 P2 450 300 133.9 582.7 P3 275 600 103.9 203.5 P4 250 600 68.0 116.3 -

[1] Gu D D, Meiners W, Wissenbach K, et al. Laser additive manufacturing of metallic components: materials, processes and mechanisms[J]. International Materials Reviews, 2013, 57(3): 133-164. [2] Vafadar A , Guzzomi F, Rassau A, et al. Advances in metal additive manufacturing: a review of common processes, industrial applications, and current challenges[J]. Applied Sciences, 2021, 11(3): 1213. [3] King W E, Anderson A T, Ferencz R M, et al. Laser powder bed fusion additive manufacturing of metals; physics, computational, and materials challenges[J]. Applied Physics Reviews, 2015, 2(4): 44-6270. [4] Du C, Zhao Y , Jiang J, et al. Pore defects in laser powder bed fusion: formation mechanism, control method, and perspectives[J]. Journal of Alloys and Compounds, 2023, 944(000): 31. [5] Polonsky A T, Pollock T M. Closing the science gap in 3D metal printing[J]. Science, 2020, 368(6491): 583-584. doi: 10.1126/science.abb4938 [6] Cunningham R, Zhao C, Parab N, et al. Keyhole threshold and morphology in laser melting revealed by ultrahigh-speed x-ray imaging[J]. Science., 2019, 363(6429): 849-852. doi: 10.1126/science.aav4687 [7] Corde S, Ta Phuoc K, Lambert G, et al. Femtosecond x rays from laser-plasma accelerators[J]. Reviews of Modern Physics, 2013, 85(1): 1-48. doi: 10.1103/RevModPhys.85.1 [8] Zhang H, Deng Z G, Jiang H, et al. High-brightness betatron X-ray source driven by the SULF-1 PW laser[J]. High Power Laser Science and Engineering, 2025, 13: e31. doi: 10.1017/hpl.2025.17 [9] Zhao C, Shi B, Chen S, et al. Laser melting modes in metal powder bed fusion additive manufacturing[J]. Reviews of Modern Physics, 2022, 94: 045002. doi: 10.1103/RevModPhys.94.045002 -

下载:

下载: