A study of frequency correction methods for integrally processed rectangular resonant cavities

-

摘要: 谐振腔作为速调管的重要组成部分,其特性对速调管的性能具有决定性影响。在高波段速调管领域,受加工工艺和焊接技术的限制,多采用一体化加工的矩形谐振腔。传统的一体化矩形谐振腔在进行频率调节时容易产生谐振腔频率偏差,频率偏差较大时会导致谐振腔无法使用等问题。据此,提出了一种实用新型频率调节结构。将该结构应用于矩形谐振腔时,可实现大幅度的频率调节,有效补偿因零件加工公差导致的频率偏差。应用此结构后,频率调节操作变得简便、快速,可以显著提升速调管的研制效率,为高波段速调管的优化与发展提供了新的技术路径。Abstract:

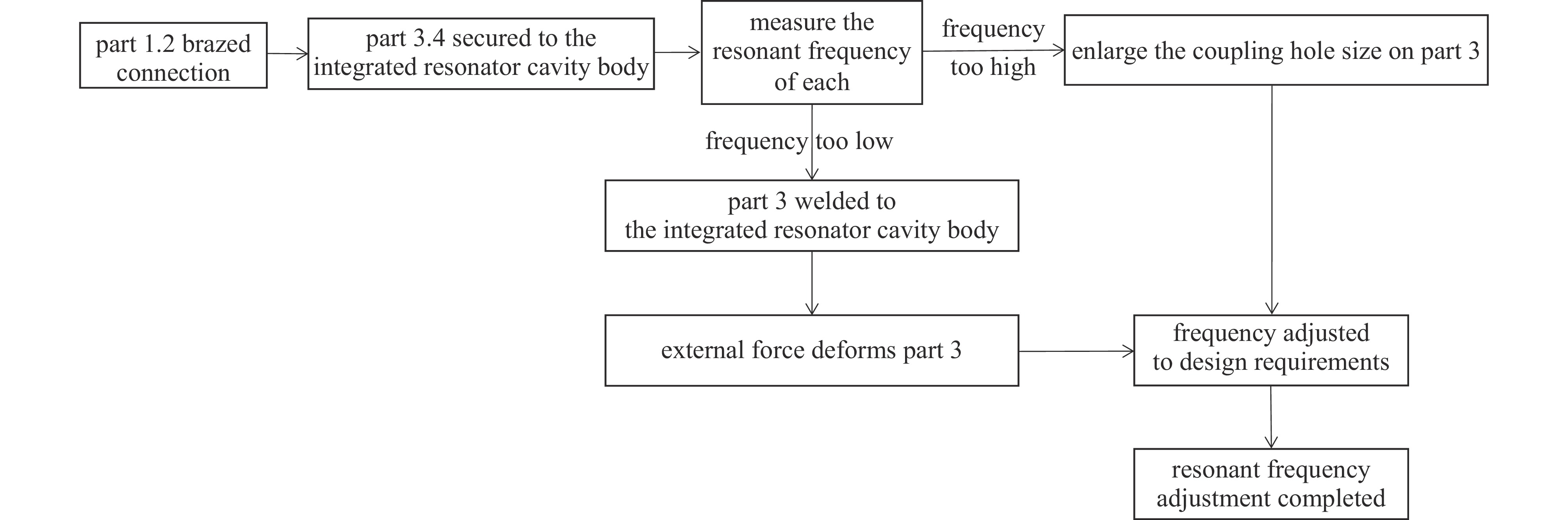

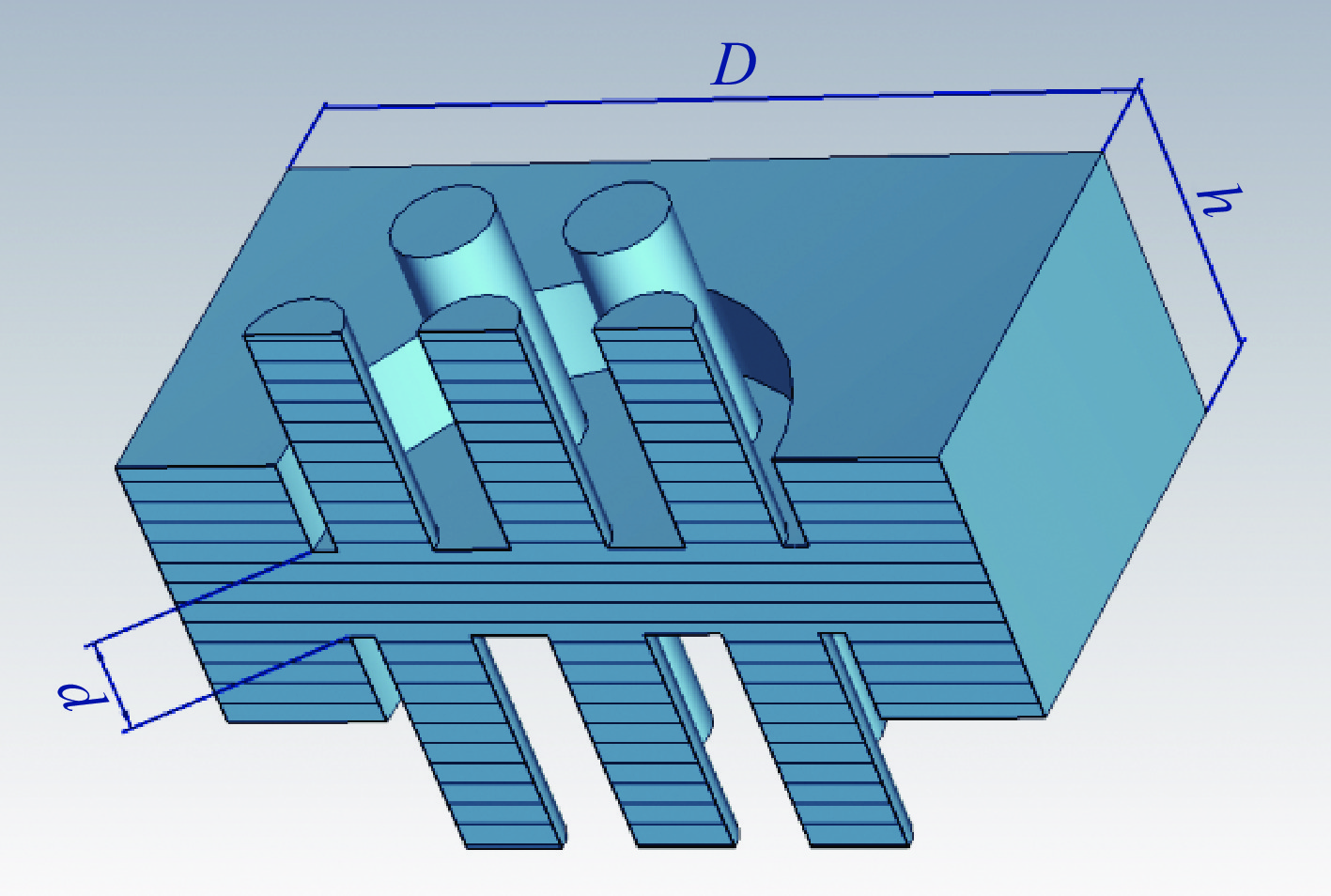

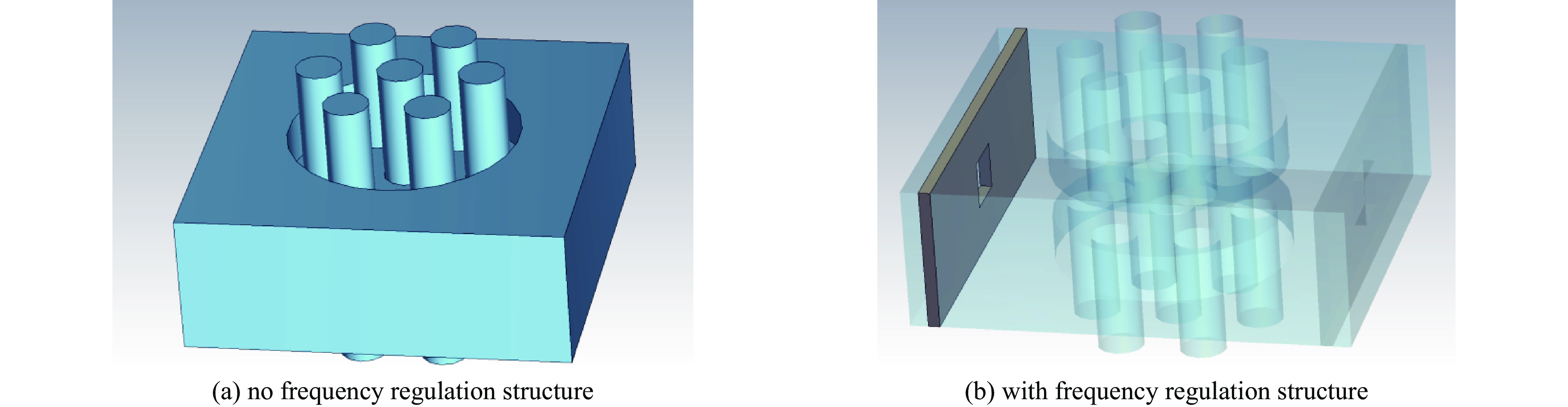

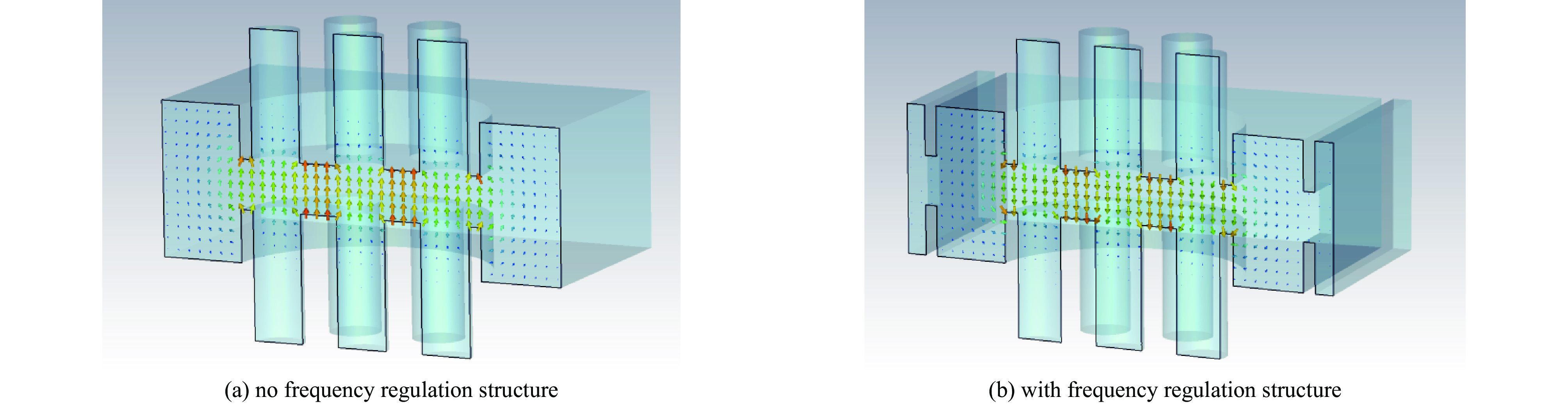

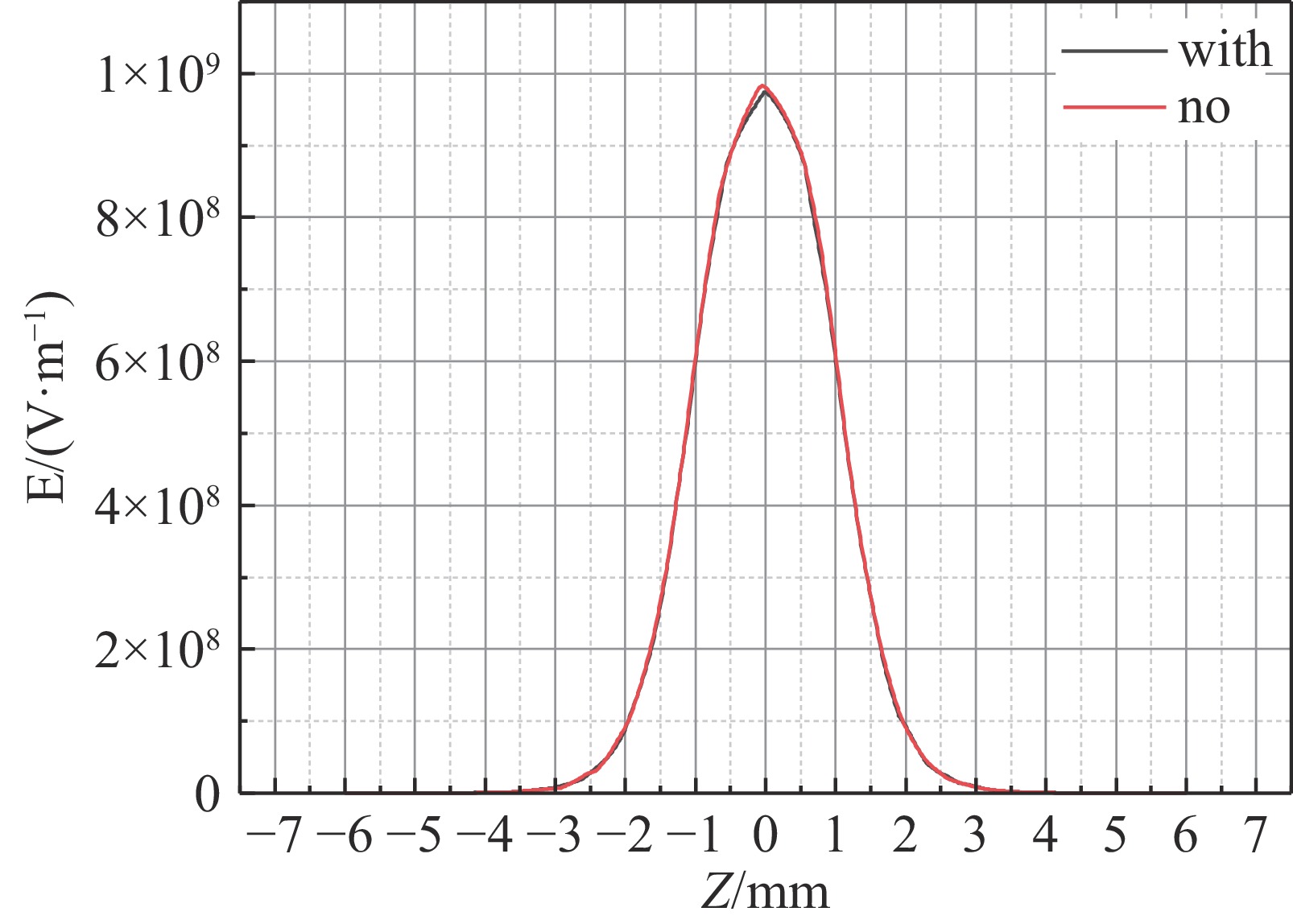

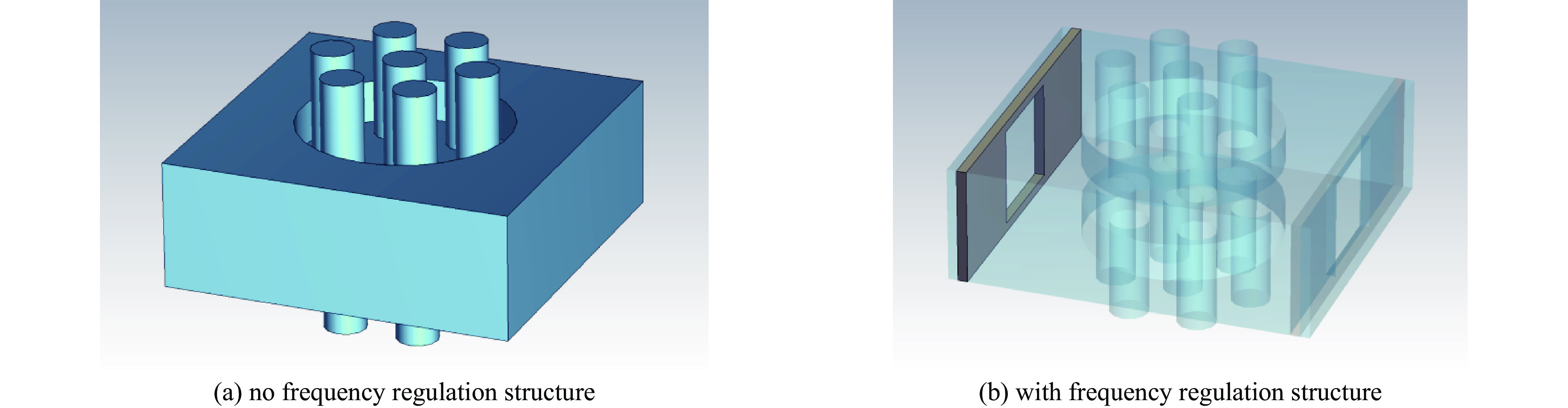

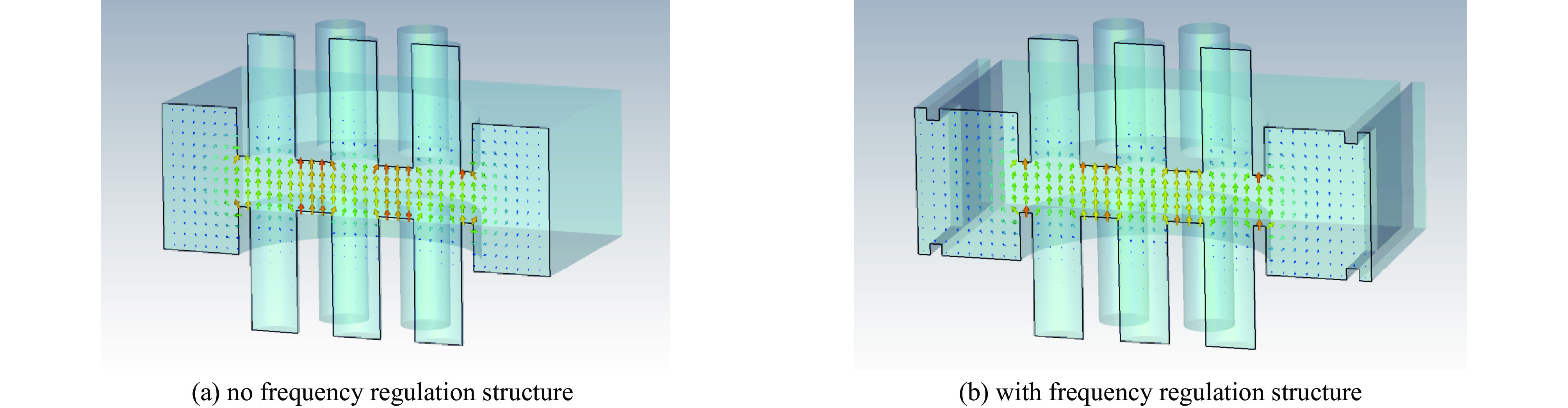

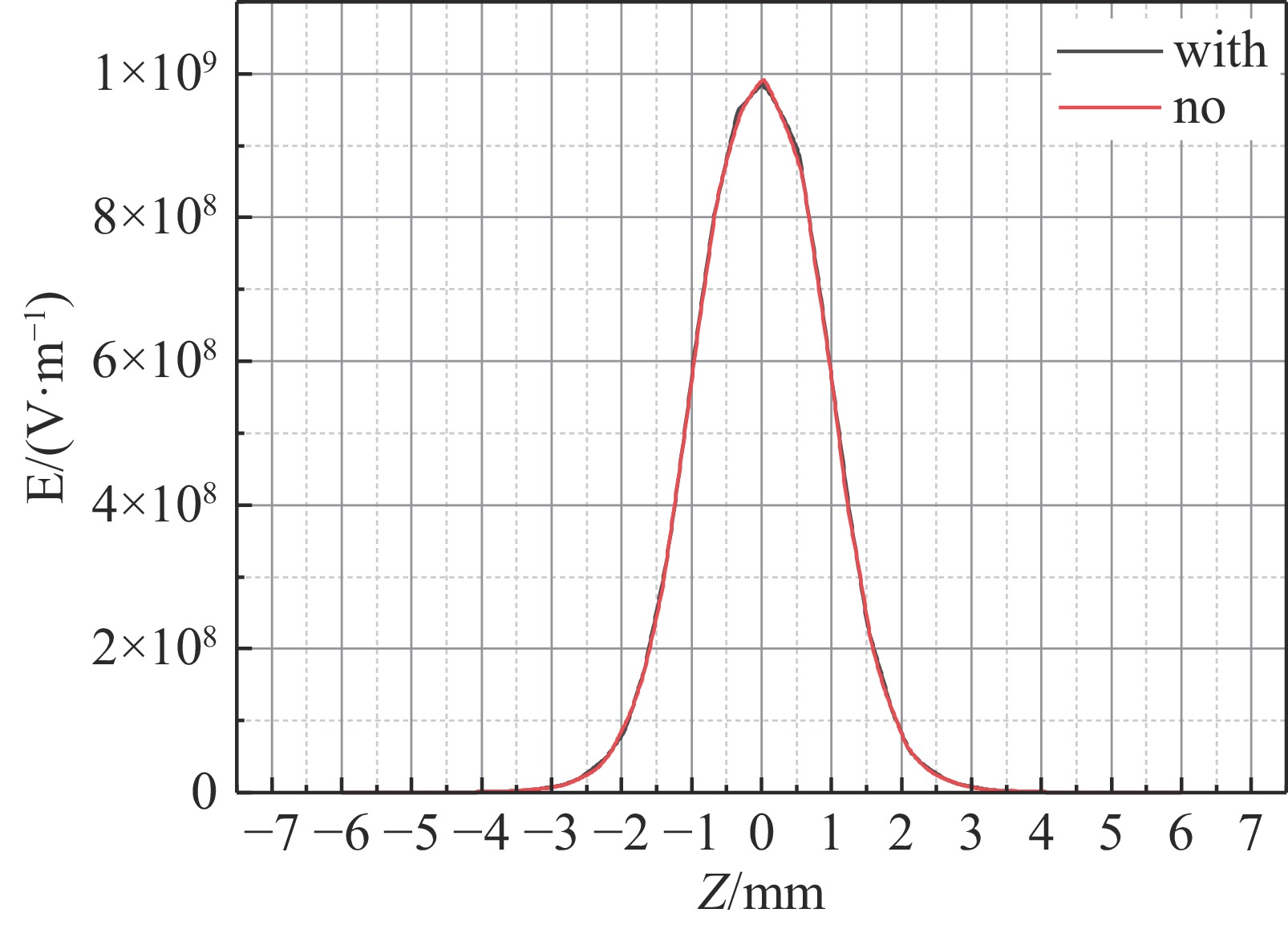

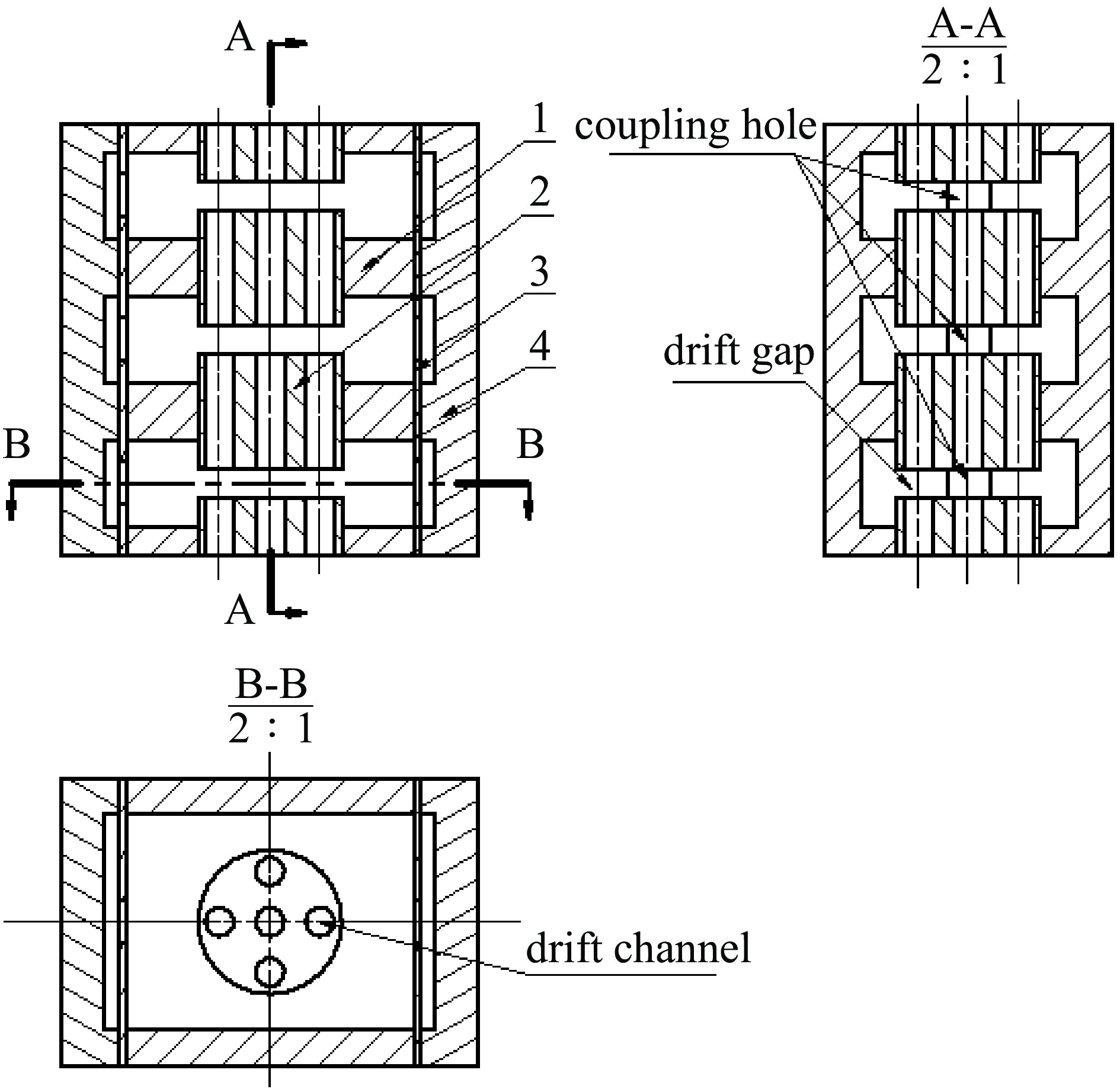

Background As an important part of klystrons, the characteristics of the resonant cavity have a decisive influence on the performance of klystrons. In the field of high-band klystrons, due to the limitation of processing technology and welding technology, the integrally processed rectangular resonant cavity is mostly used.Purpose The traditional integrally processed rectangular resonant cavity is prone to problems such as frequency deviation of the resonant cavity or even inoperability of the resonant cavity when frequency adjustment is performed.Methods Accordingly, this paper innovatively proposes a practical new frequency-modulation structure: a coupling diaphragm with slots cut into the resonator cavity walls and openings added.Results Simulation calculations validate that when this structure is applied to the rectangular resonant cavity, a large-scale frequency adjustment can be achieved, effectively compensating for the frequency deviation caused by the machining tolerance of parts.Conclusions During frequency tuning, applying external force deforms the diaphragm to increase cavity frequency, while enlarging the coupling aperture on the diaphragm lowers it. Moreover, the frequency adjustment operation becomes simple and rapid, significantly improving the research and development efficiency of the klystron, thus providing a new technical approach for the optimization and development of high-band klystrons. -

表 1 谐振腔尺寸及对应的谐振频率和R/Q

Table 1. Resonant cavity size and corresponding resonant frequency and R/Q

Parameter D/mm D/mm H/mm F/MHz R/Q nominal value 16.5 2 6 8464 52.5 tolerance 16.5+0.05 2-0.05 6+0.05 8343 50.3 表 2 谐振腔尺寸及对应的谐振频率和R/Q

Table 2. Resonant cavity size and corresponding resonant frequency and R/Q

Parameter D/mm D/mm H/mm F/MHz R/Q nominal value 16.5 2 6 8464 52.5 tolerance 16.5-0.05 2+0.05 6-0.05 8630 52.3 -

[1] 罗芸芸, 林福民, 刘美希, 等. 用于速调管的一维光子晶体圆柱腔分析[J]. 电子器件, 2015, 38(2): 245-249Luo Yunyun, Lin Fumin, Liu Meixi, et al. Analysis of one-dimensional photonic crystal cylindrical cavity for klystron[J]. Chinese Journal of Electron Devices, 2015, 38(2): 245-249 [2] 丁耀根. 大功率速调管的技术现状和最新进展[J]. 真空电子技术, 2020(1): 1-25Ding Yaogen. Technical status and latest progress of high power klystrons[J]. Vacuum Electronics, 2020(1): 1-25 [3] 丁耀根, 刘濮鲲, 张兆传, 等. 大功率速调管的技术现状和研究进展[J]. 真空电子技术, 2010(6): 1-8,11Ding Yaogen, Liu Pukun, Zhang Zhaochuan, et al. The state art and research progresses of high power klystron[J]. Vacuum Electronics, 2010(6): 1-8,11 [4] 丁耀根, 刘濮鲲, 张兆传, 等. 真空电子学和微波真空电子器件的发展和技术现状[J]. 微波学报, 2010, 26(s1): 397-400Ding Yaogen, Liu Pukun, Zhang Zhaochuan, et al. The state art and development of vacuum electronics and microwave vacuum electron devices[J]. Journal of Microwaves, 2010, 26(s1): 397-400 [5] 刘盛纲. 太赫兹科学技术的新发展[J]. 中国基础科学, 2006, 8(1): 7-12Liu Shenggang. Recent development of terahertz science and technology[J]. China Basic Science, 2006, 8(1): 7-12 [6] 陈新桥. 一种大功率微波器件—速调管[J]. 湖北民族学院学报(自然科学版), 2001, 19(1): 70-72Chen Xinqiao. Klystron-a high power microwave device[J]. Journal of Hubei Minzu University (Natural Science Edition), 2001, 19(1): 70-72 [7] 丁耀根. 大功率速调管的理论与计算模拟[M]. 北京: 国防工业出版社, 2008Ding Yaogen. Theory and computer simulation of high power klystron[M]. Beijing: National Defense Industry Press, 2008 [8] 陈新桥, 朱允淑, 丁耀根. 高次模多注速调管的矩形双间隙输出腔的研究[J]. 电子与信息学报, 2003, 25(8): 1126-1129Chen Xinqiao, Zhu Yunshu, Ding Yaogen. Study of rectanglar double gap output cavity of high mode multi-beam klystron[J]. Journal of Electronics & Information Technology, 2003, 25(8): 1126-1129 [9] 谢家麟, 赵永翔. 速调管群聚理论[M]. 北京: 科学出版社, 1966: 10-56Xie Jialin, Zhao Yongxiang. Tachyon tube cluster theory[M]. Beijing: Science Press, 1966: 10-56 [10] 电子管设计手册编辑委员会. 大功率速调管设计手册[M]. 北京: 国防工业出版社, 1979: 1-6, 16-17, 57-58Electronic Tube Design Manual Editorial Board. High power klystron design manual[M]. Beijing: National Defense Industry Press, 1979: 1-6, 16-17, 57-58 [11] 丁耀根. 大功率速调管的设计制造和应用[M]. 北京: 国防工业出版社, 2010Ding Yaogen, Design, manufacture and application of high power klystron[M]. Beijing: National Defense Industry Press, 2010 [12] 都培伟, 杨中海, 梁源. 双间隙输出腔速调管的注波互作用程序分析[J]. 真空电子技术, 2008(6): 23-26Du Peiwei, Yang Zhonghai, Liang Yuan. Analysis of beam-wave interaction program of klystron with double-gap output cavity[J]. Vacuum Electronics, 2008(6): 23-26 [13] 付强, 王东振, 化麒, 等. 某型雷达导引头速调管故障分析及质量优化[J]. 航空维修与工程, 2021(12): 74-76Fu Qiang, Wang Dongzhen, Hua Qi, et al. Fault analysis and quality optimization of klystron for a certain type of radar seeker[J]. Aviation Maintenance & Engineering, 2021(12): 74-76 [14] 汪海洋, 李明光, 李家胤. 多注速调管双重入式谐振腔的解析计算与仿真[J]. 强激光与粒子束, 2002, 14(3): 421-425Wang Haiyang, Li Mingguang, Li Jiayin. Analysis and simulation for double reentrant cavity of multiple-beam klystron[J]. High Power Laser and Particle Beams, 2002, 14(3): 421-425 [15] 曹静, 高冬平, 时全局. 一体化矩形谐振腔加载方法研究[C]//第二十二届真空电子学学术年会论文集. 2024: 244-247Cao Jing, Gao Dongping, Shi Quanju. Research on loading method of integrally processed rectangular resonant cavity[C]//Proceedings of the 22nd Annual Vacuum Electronics Conference. 2024: 244-247 -

下载:

下载: