Lifetime characteristics of mica capacitor under microsecond pulse

-

摘要: 近年来,快速发展的卷绕式云母纸电容器较大地提升了其工作电压,有希望用于提升PFN-Marx(pulse forming line - Marx)发生器的整体储能密度水平。电容器寿命是确保装置可靠性的重要因素,而该电容器的寿命特性尚未清楚,其最优工作条件和装置的预期工作寿命未能明确。基于此,开展了微秒脉冲下云母电容寿命特性的预测模型和实验研究。首先,分析了云母电容的内部结构,建立仿真模型并进行了电场、热场模拟分析。其次,搭建了一个能够稳定长时间工作的寿命测试平台,通过该平台获取并分析了云母电容的退化参数、寿命数据和失效机理。根据寿命数据结果,本文修正了在给定运行因素下的云母电容寿命预测模型。结果表明,寿命预测模型与寿命测试结果基本匹配。研究工作将有助于发展云母电容的寿命预测,并为在微秒脉冲下使用云母电容的系统装置设计提供参考。Abstract:

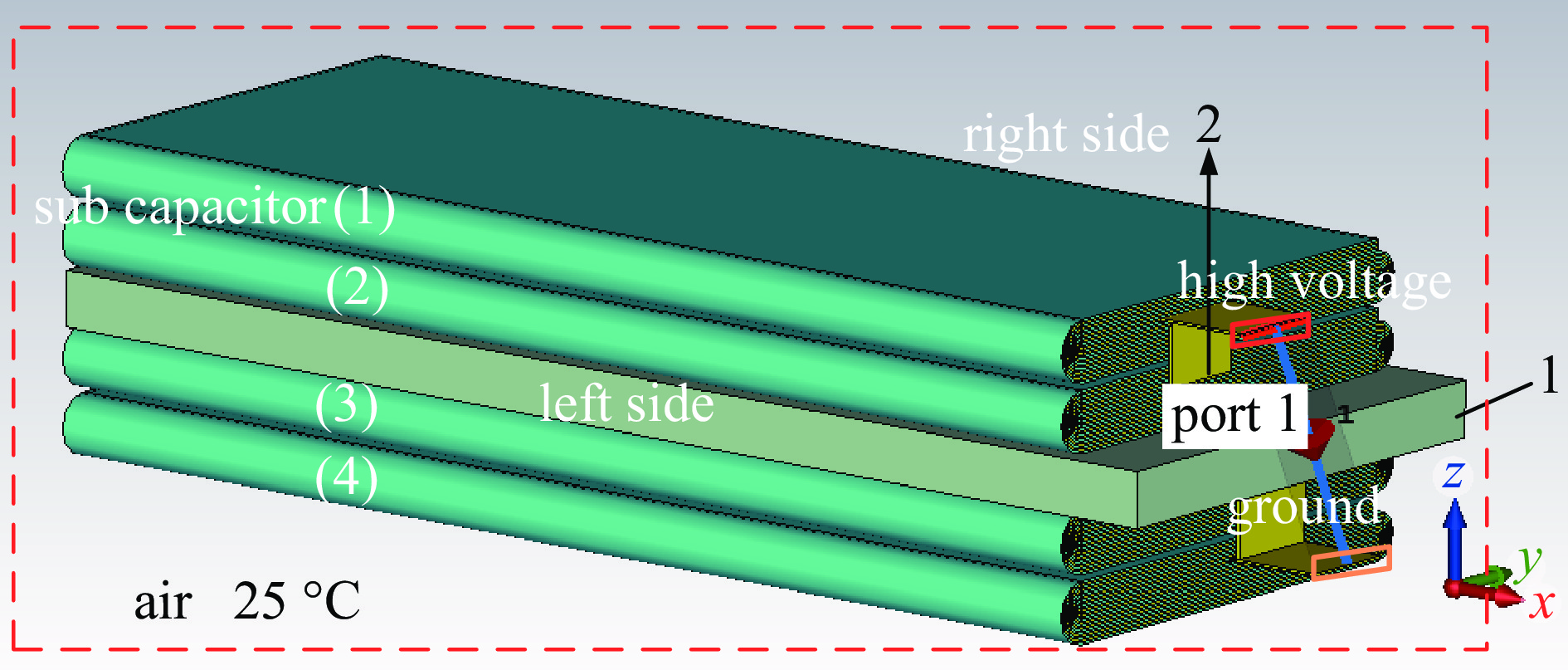

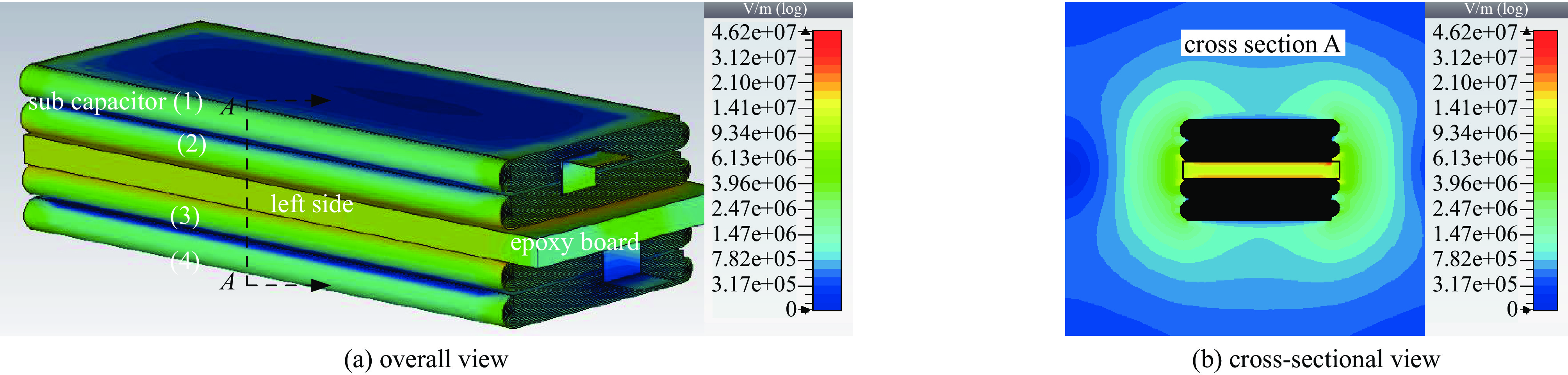

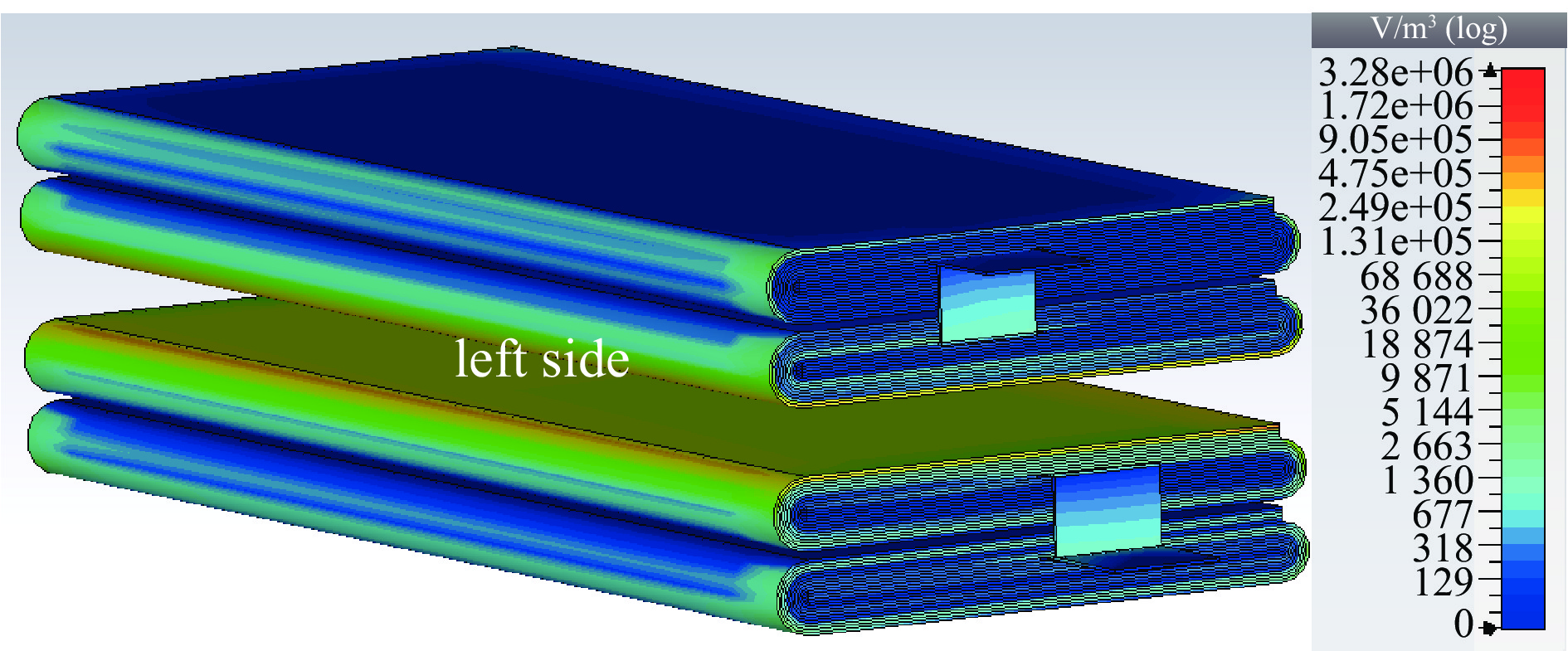

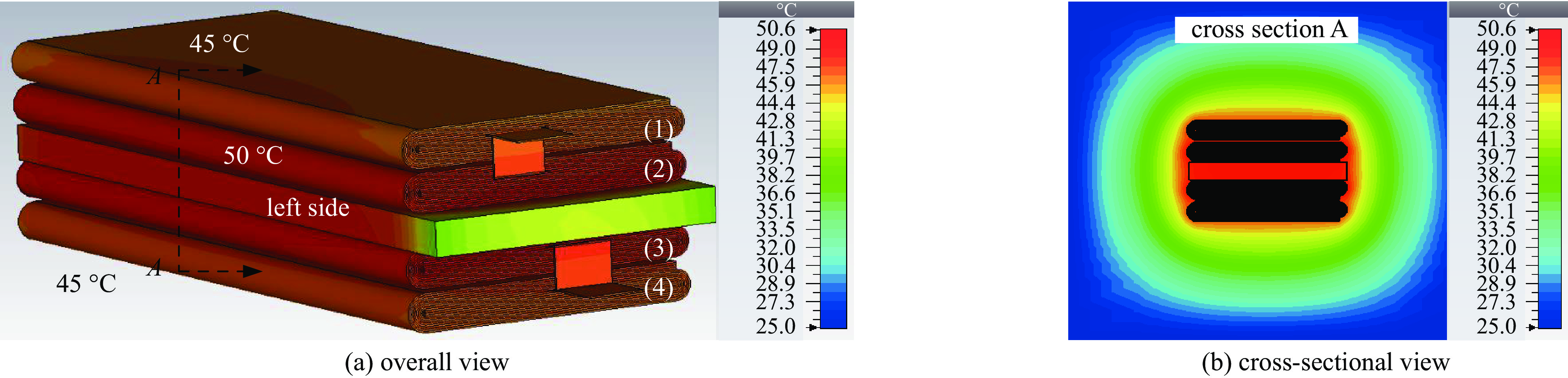

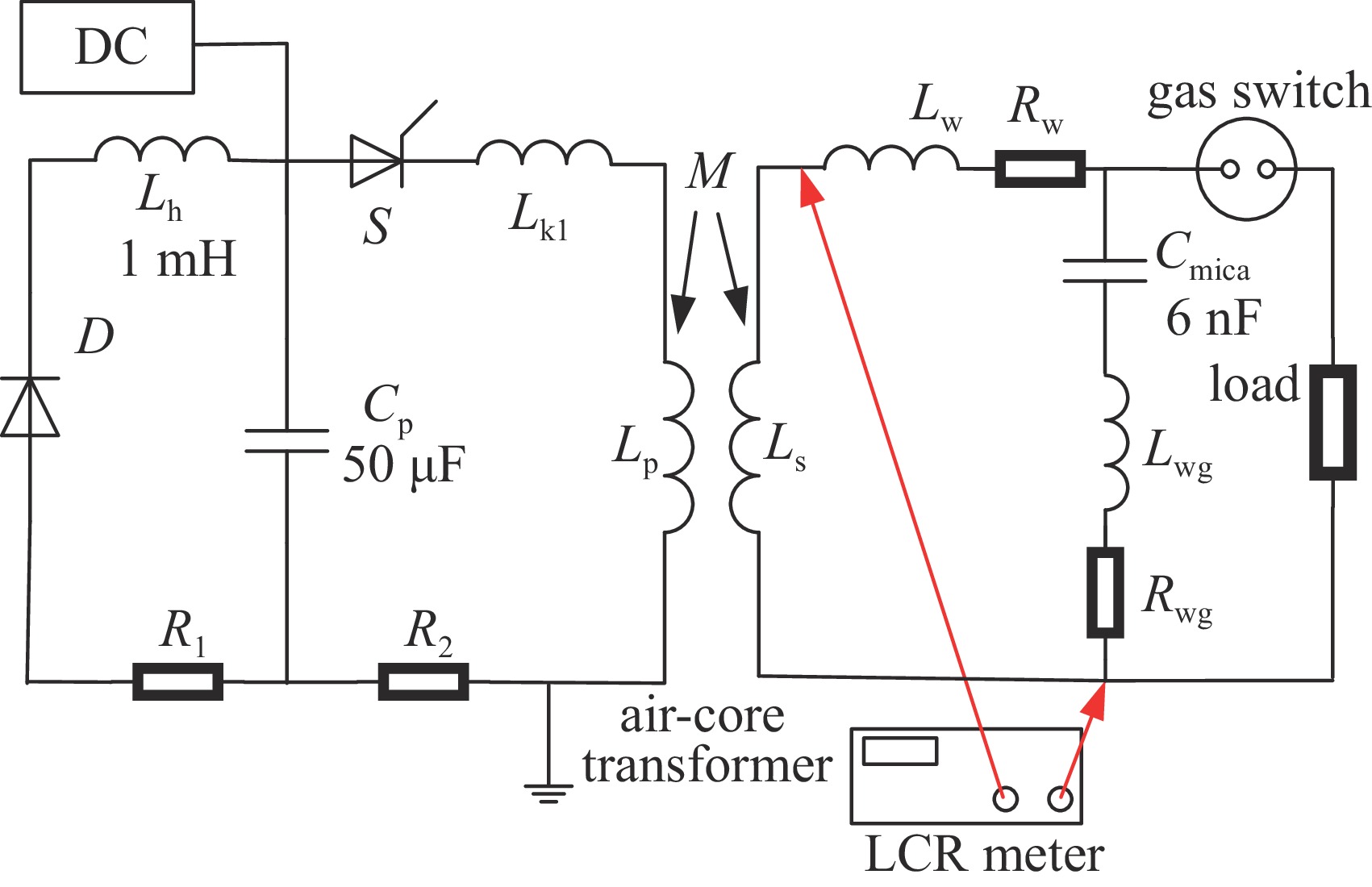

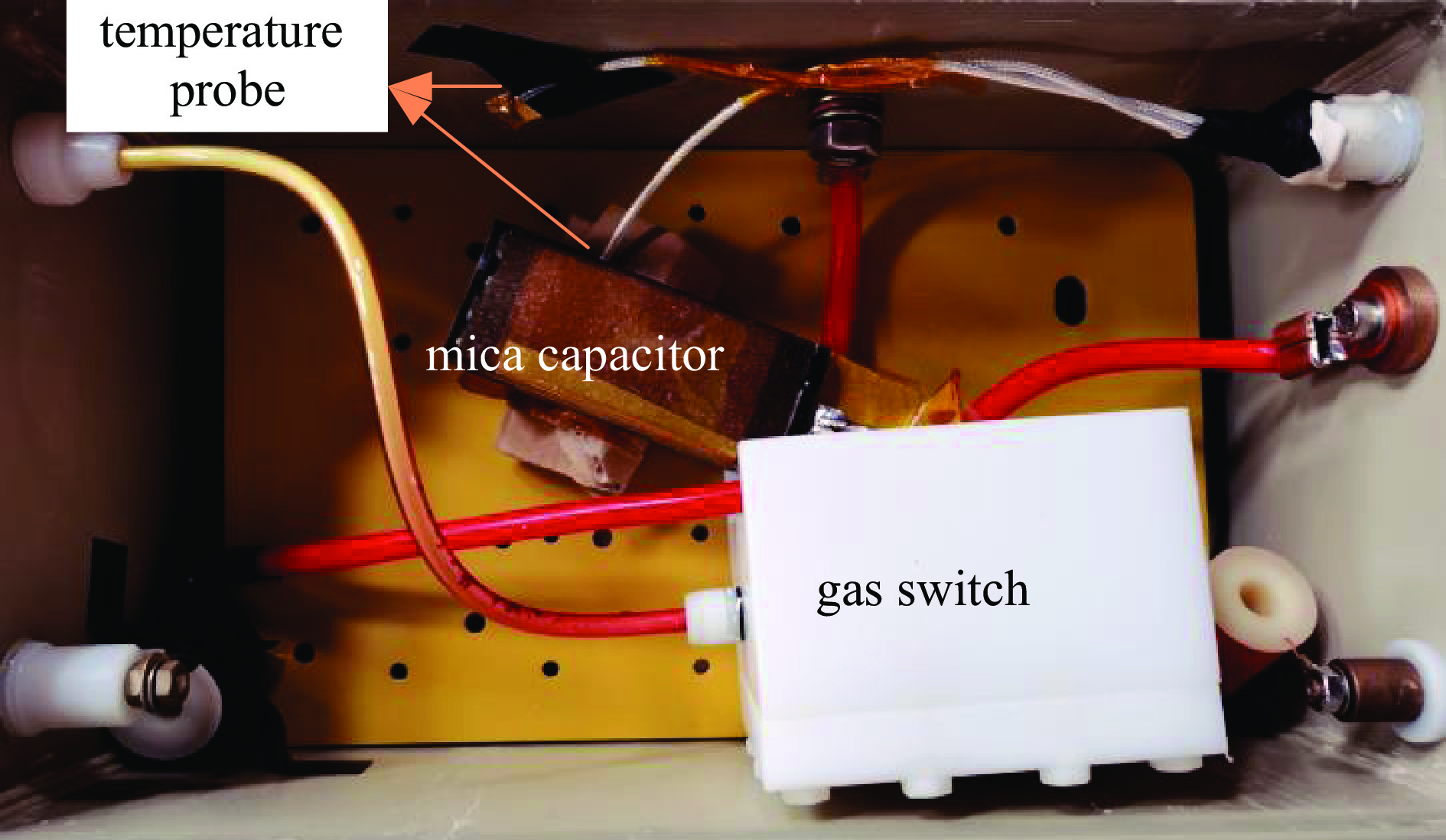

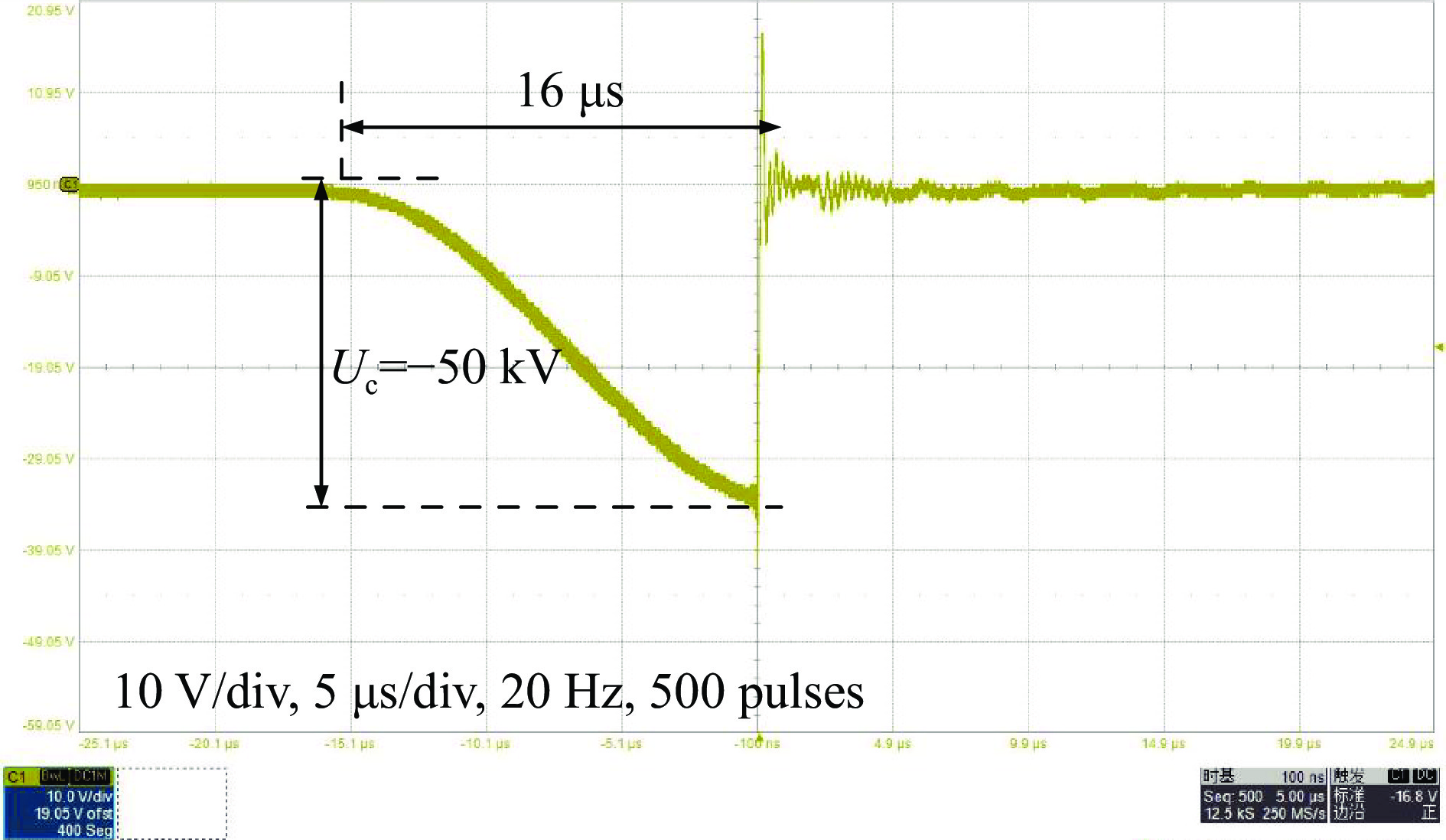

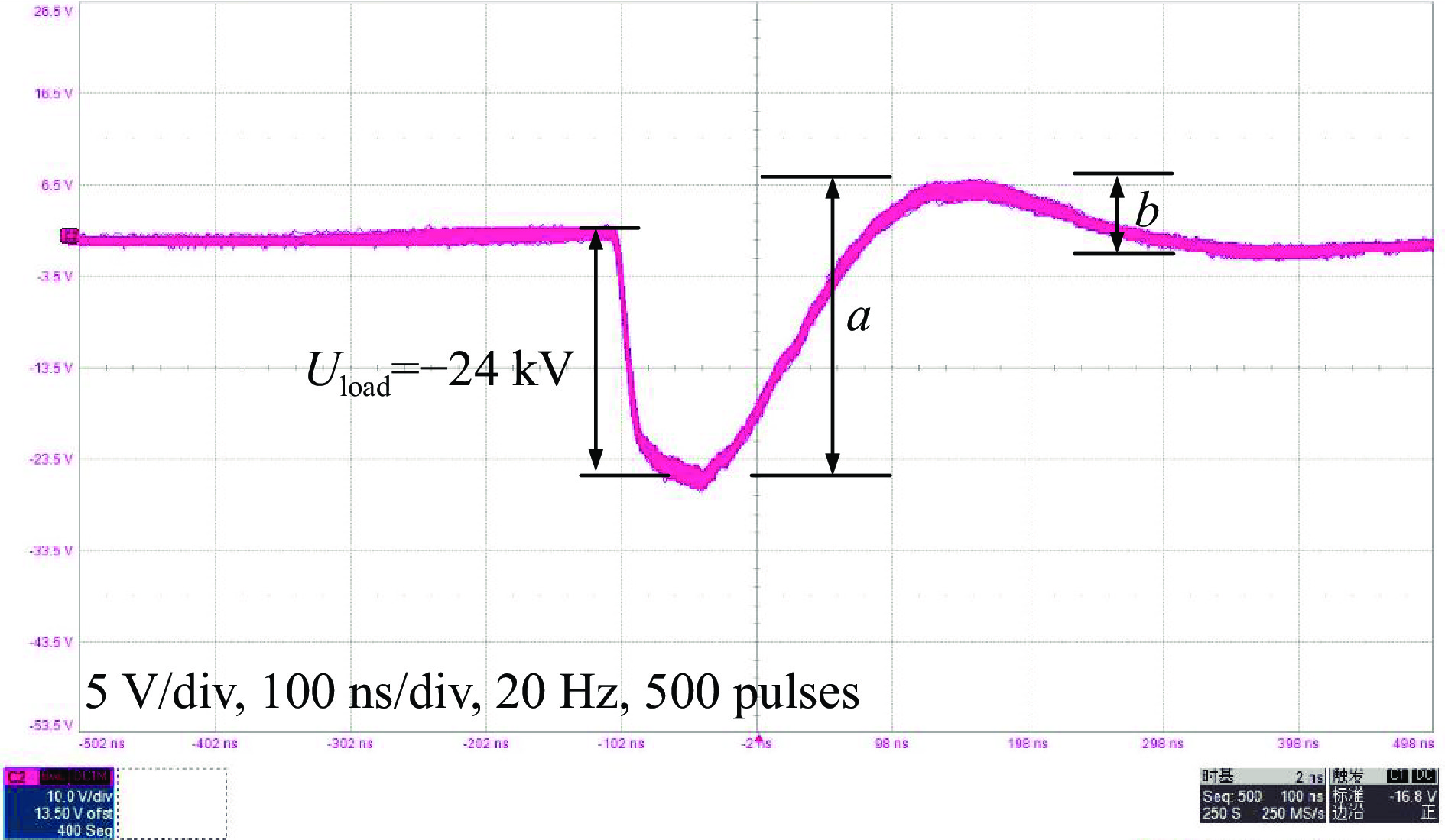

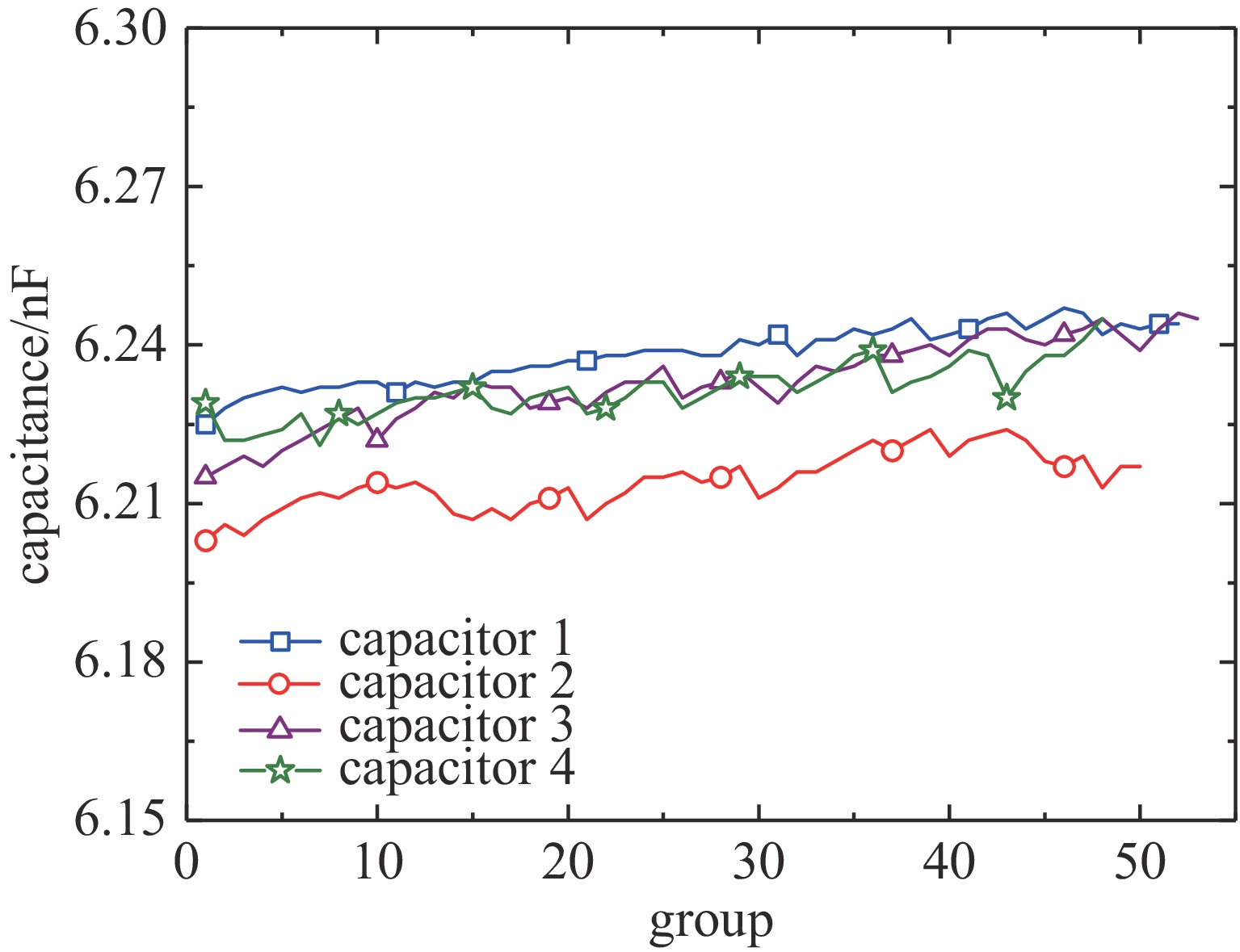

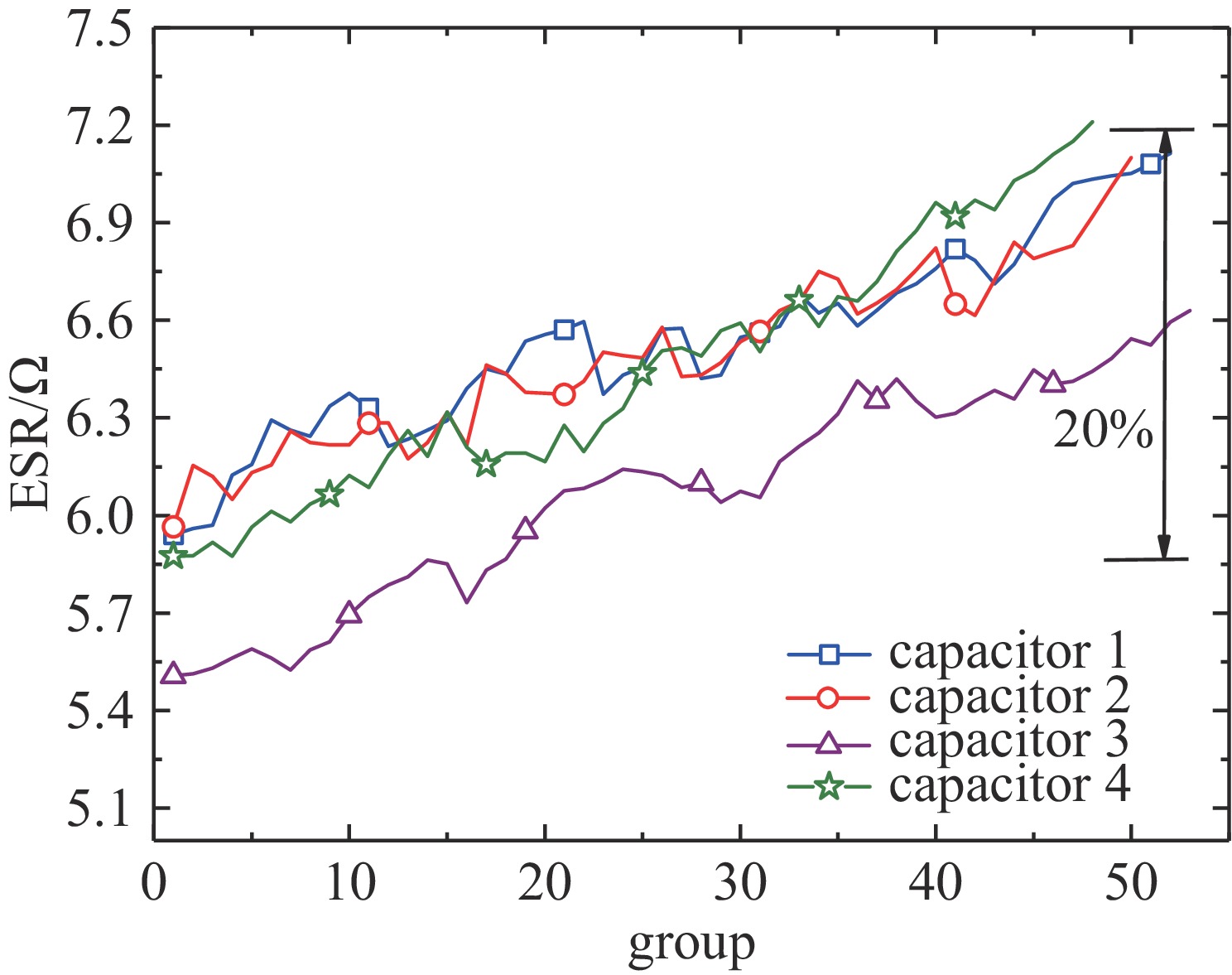

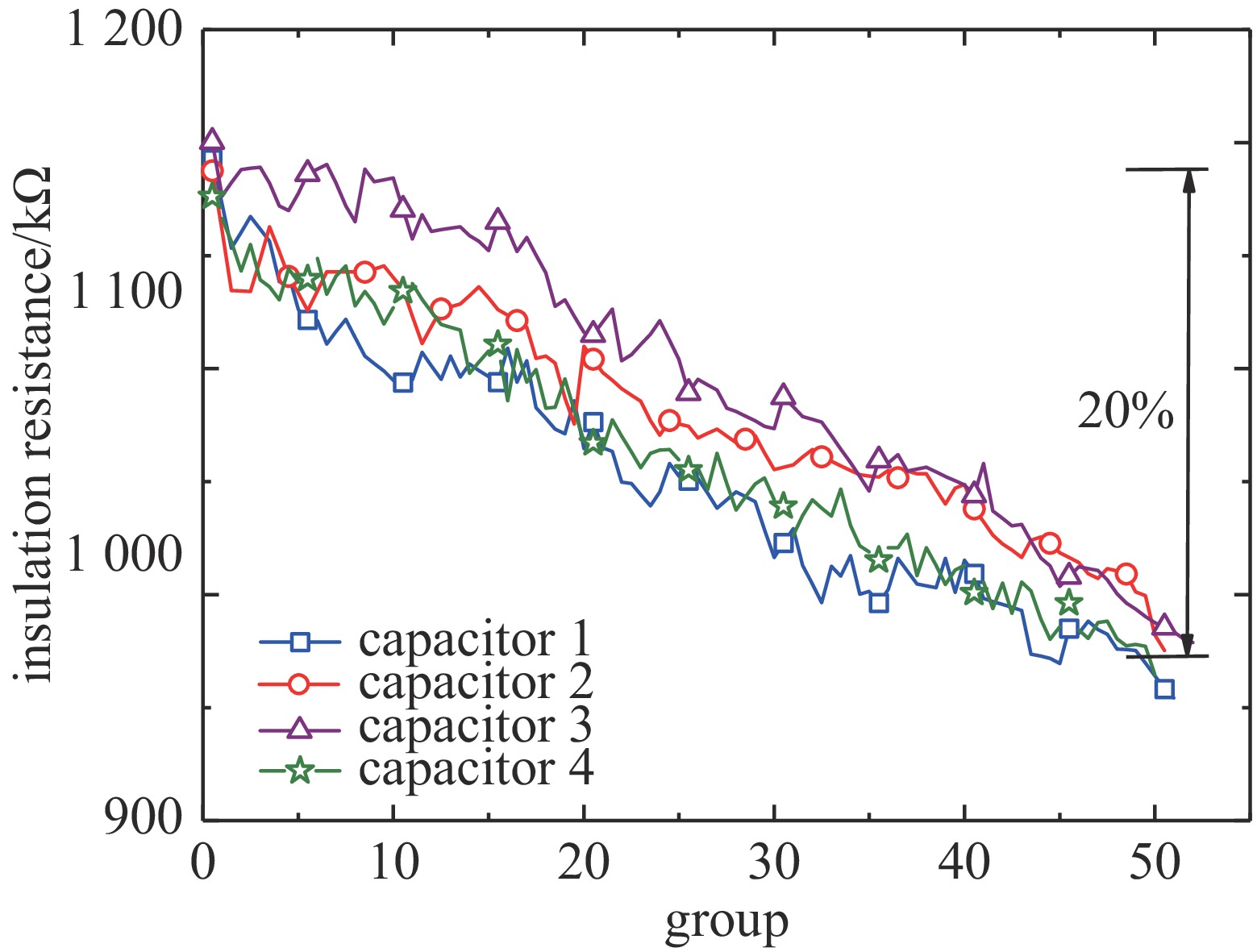

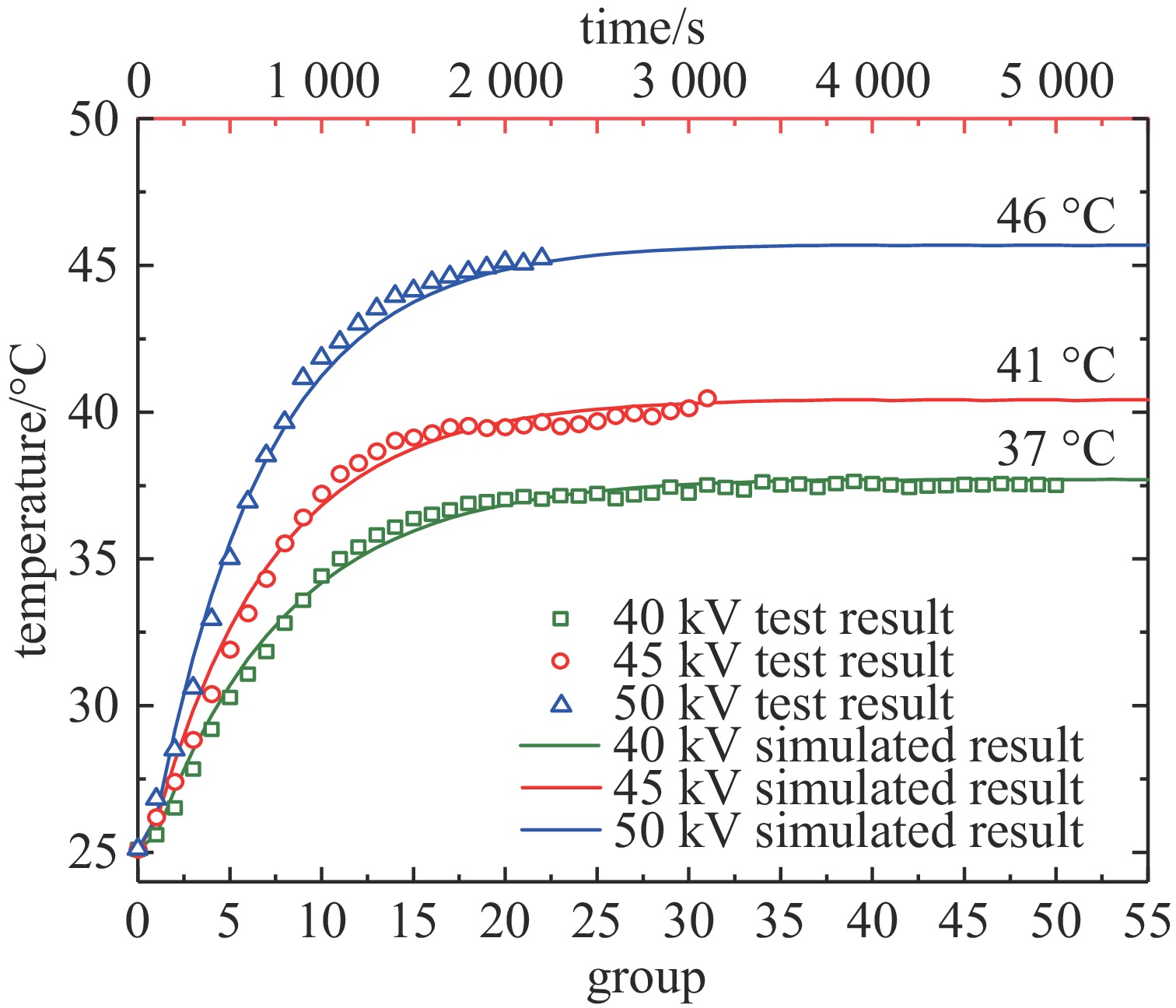

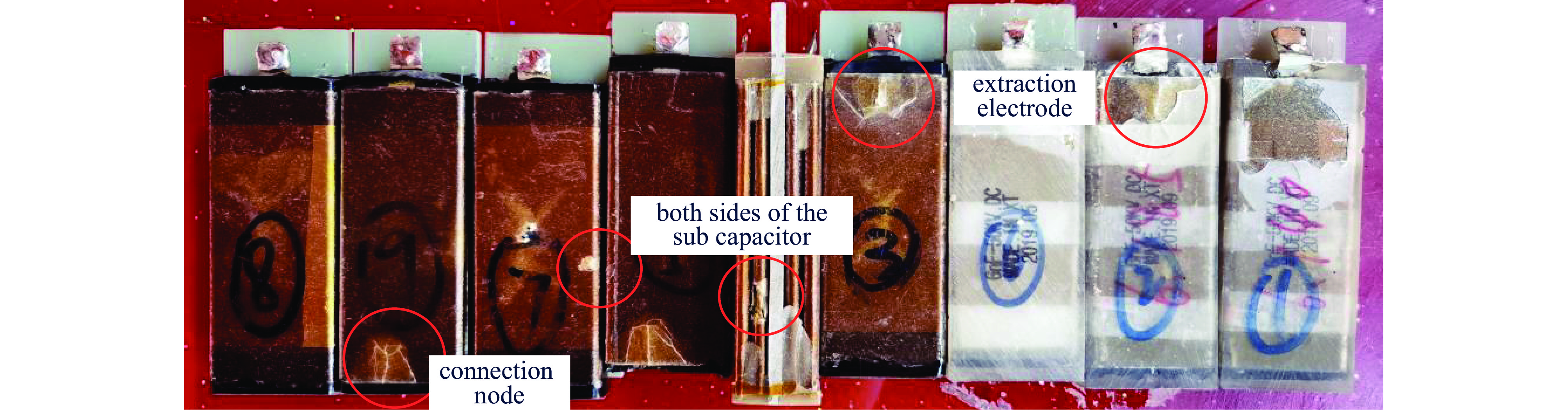

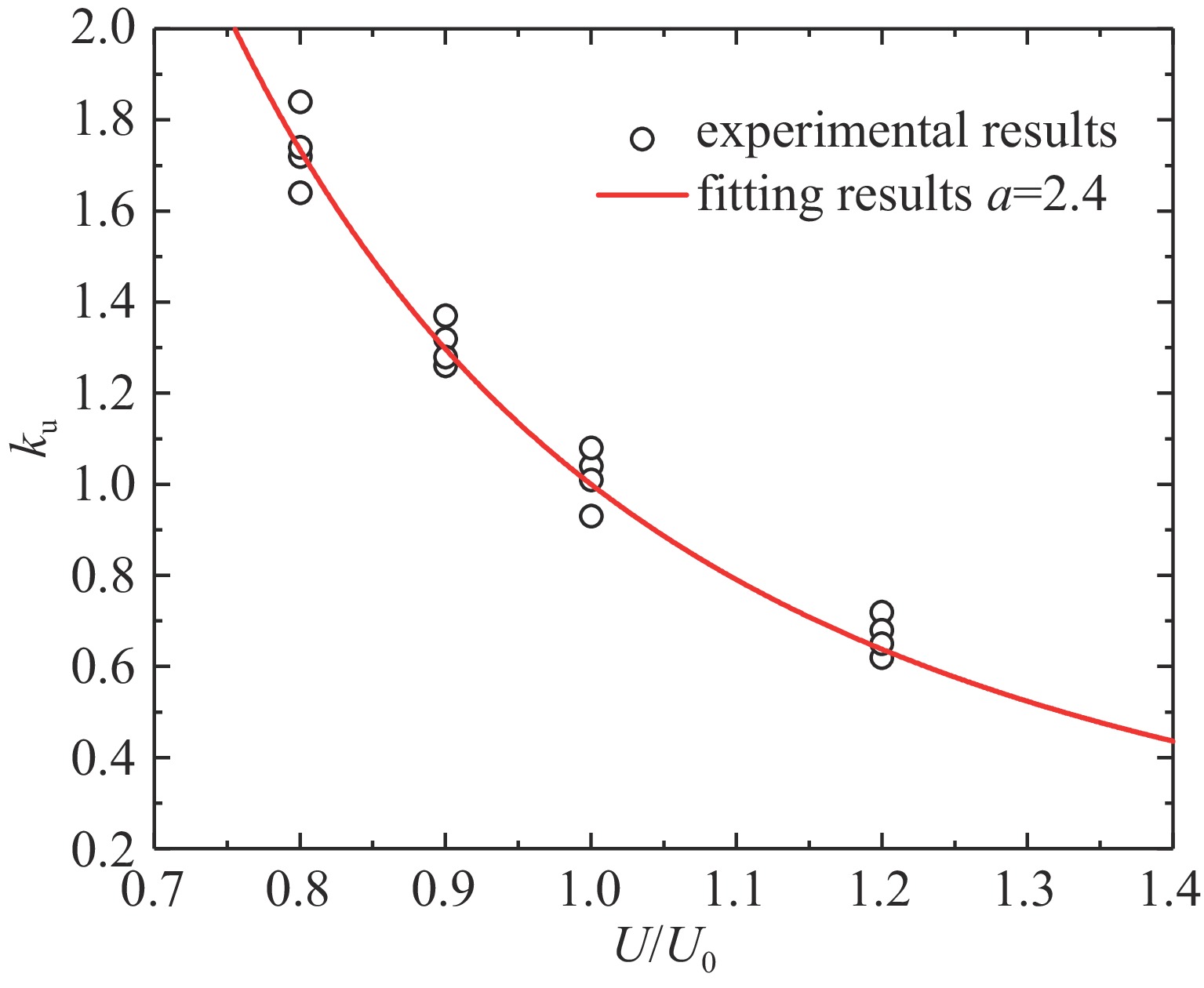

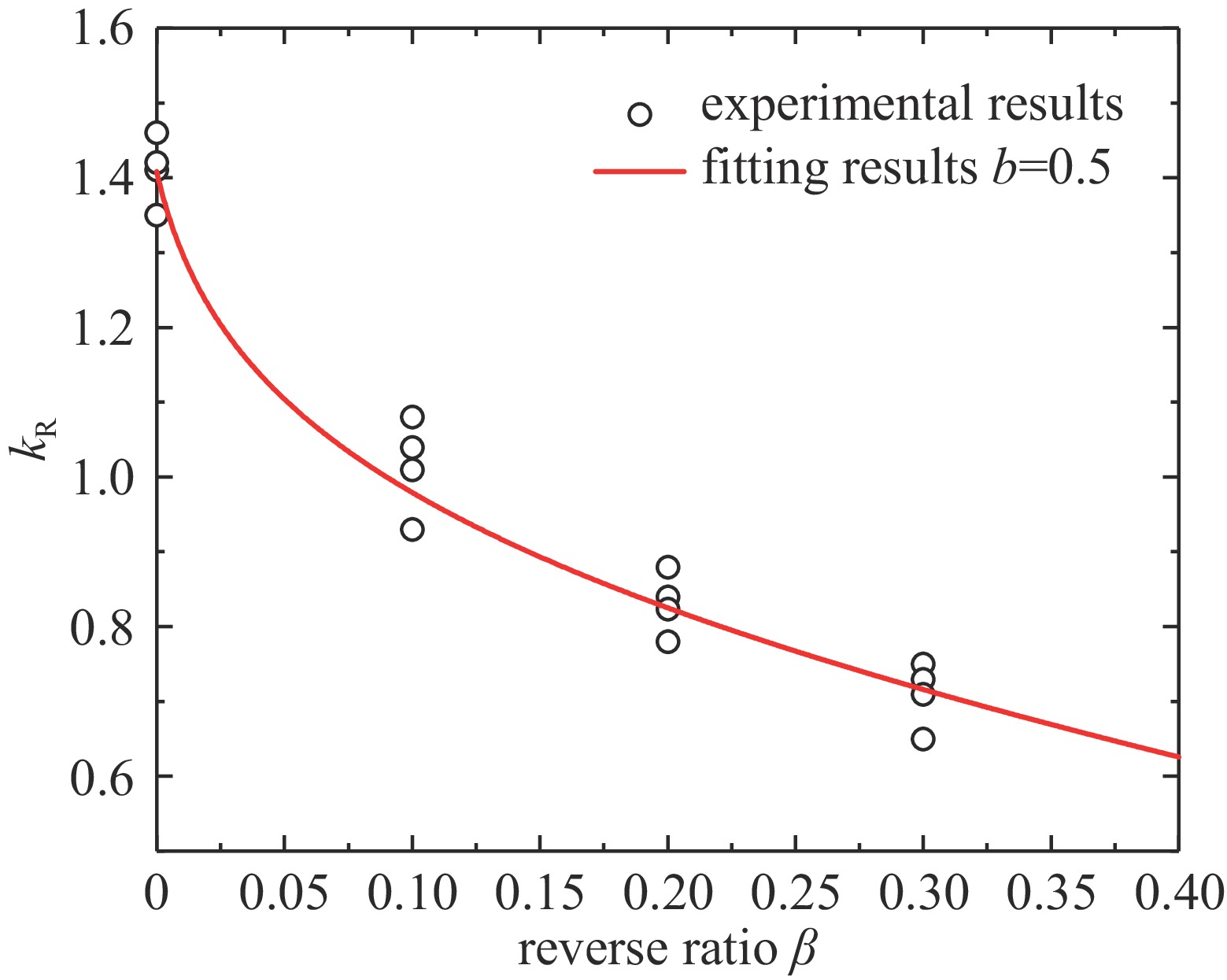

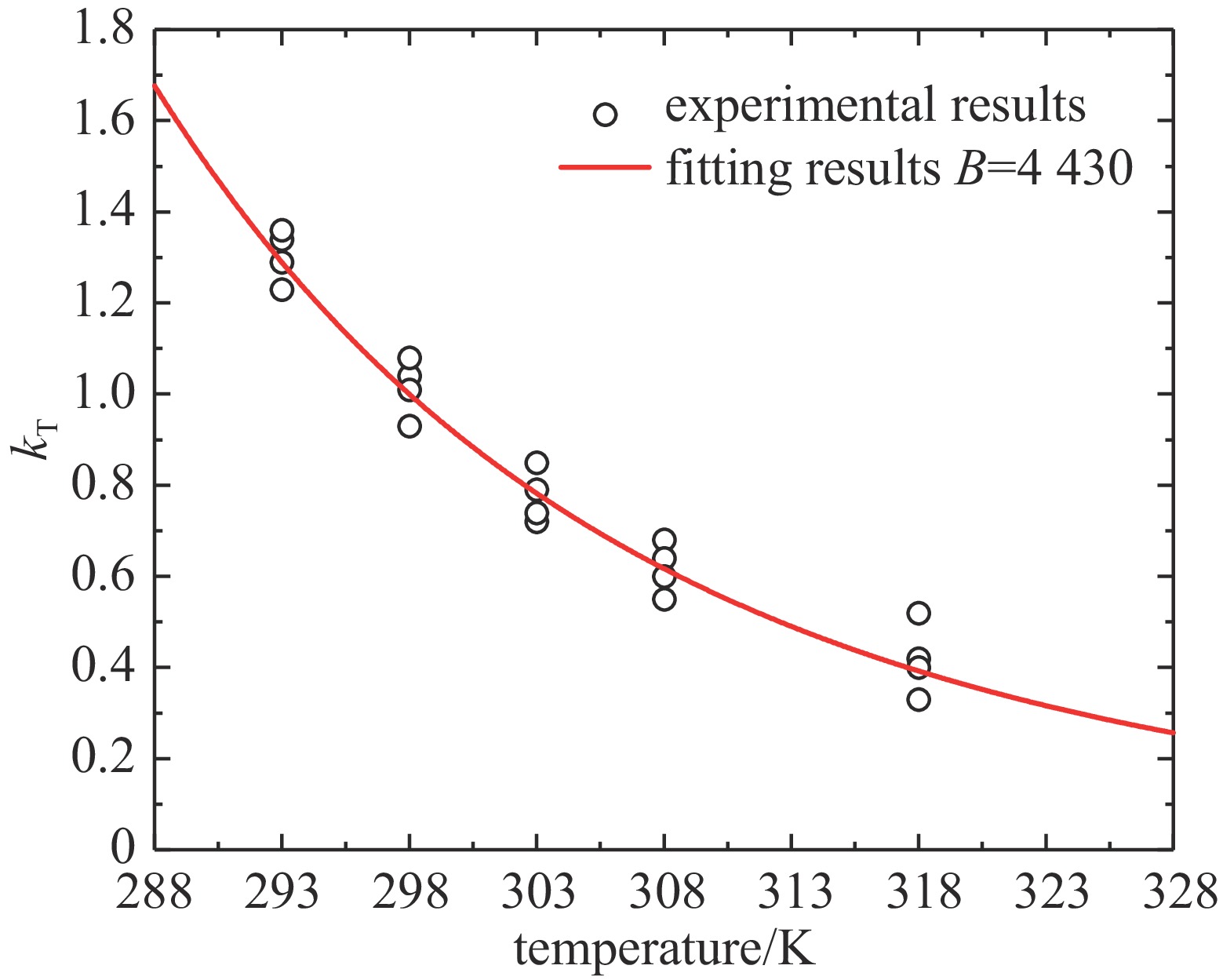

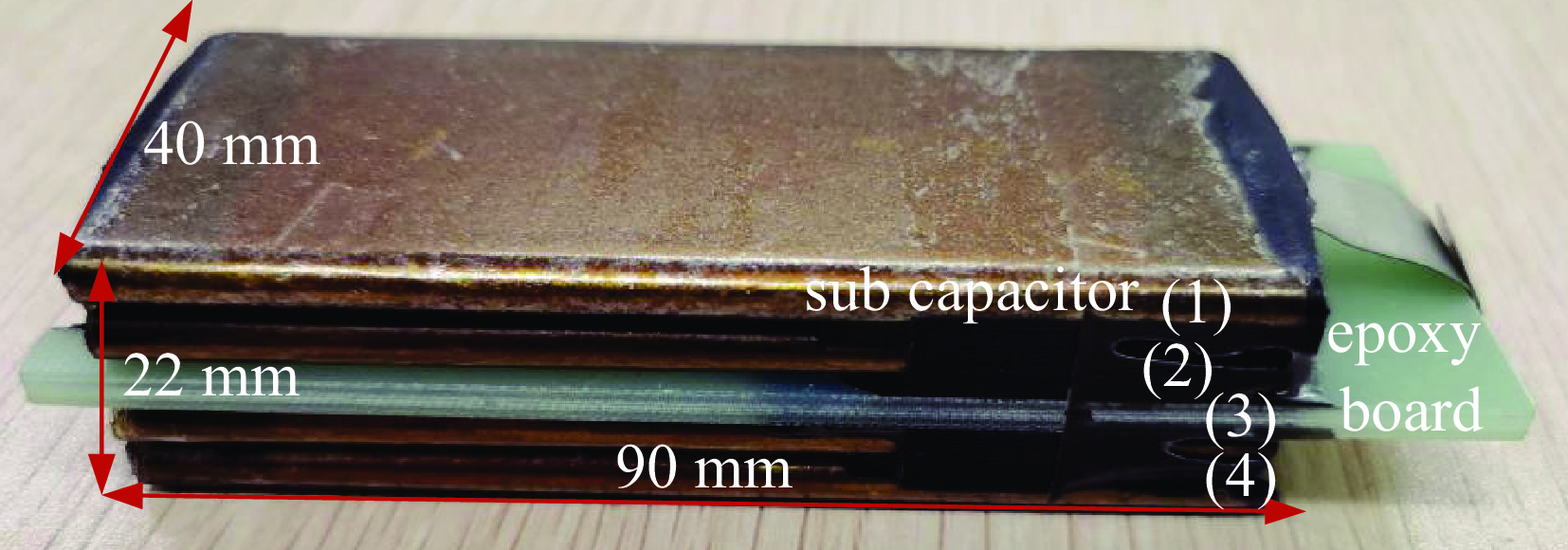

Background In recent years, the development of wound-type mica paper capacitors has significantly enhanced their operating voltage and energy density, and they remain highly reliable, showing potential for improving the overall energy storage density of PFN (pulse forming line)-Marx generators.Purpose The lifetime of the capacitor is a crucial factor in ensuring system reliability. The lifetime of the mica paper capacitor reaches up to 100,000 times, meeting the requirements of highly compact pulse power drivers. However, the lifetime characteristics of this capacitor remain unclear, and its optimal operating conditions have not been well-defined.Methods In this paper, an investigation into the lifetime characteristics of mica paper capacitors under microsecond pulses is presented. First, the structure of the capacitor is analyzed in detail. Subsequently, numerical simulations of the electrical and thermal fields are carried out to further study its characteristics. To accurately test the mica paper capacitors, a lifetime test platform that can operate stably over an extended period was constructed.Results Through the utilization of this platform, the electrical degradation parameters and the failure mechanisms of the mica paper capacitors are obtained and analyzed. Based on the test data, the lifetime empirical model of mica capacitors under given operating conditions is modified.Conclusions The results of the experiments and calculations of the lifetime empirical model indicate that the model aligns well with the experimental results. This work contributes to the lifetime prediction of mica capacitor and provides design reference for system devices using mica capacitor under microsecond pulses. -

表 1 电场仿真的材料参数

Table 1. Material parameters of electric field simulation

material relative

permittivityconductivity/

(S·m−1)aluminum 1.0 3.6×107 mica 2.2 2×10−10 epoxy 3.5 − 表 2 热场仿真的材料参数

Table 2. Material parameters of thermal field simulation

material thermal

conductivity/

(W·K−1·m−1)specific heat

capacity/

(J·kg−1·K−1)density/

(kg·m−3)aluminum 238.00 900 2700 mica 0.75 500 2800 epoxy 0.20 550 1200 表 3 寿命测试结果

Table 3. Results of Lifetime test

No. Samples

numberCharging

Voltage/kVAverage

Temperature/℃Reversal

Ratio/%Average

lifetimeR-STD/% 1 40 25 10 4 173500 4.7 2 45 25 10 4 130750 4.8 3 50 25 10 4 101500 6.3 4 60 25 10 4 66750 6.4 5 50 25 0 4 141000 3.2 6 50 25 20 4 83100 5.1 7 50 25 30 4 70250 5.2 8 50 20 10 4 130500 5.8 9 50 30 10 4 77750 5.8 10 50 35 10 4 61750 5.6 11 50 45 10 4 41750 7.8 表 4 寿命预测结果

Table 4. The lifetime prediction result

Capacitor Voltage/kV Steady Temperature

of test/℃Test Result/

pulsesPredicted

Result/pulsesError/% C1 40 37 102000 95489 6.4 C2 45 40 62000 62763 −1.2 C3 50 45 42000 39015 7.1 -

[1] 曾正中. 实用脉冲功率技术引论[M]. 西安: 陕西科学技术出版社, 2003Zeng Zhengzhong. Introduction to practical pulse power technology[M]. Xi’an: Shaanxi Science and Technology Press, 2003 [2] 崔光曦, 李俊娜, 陈旭良, 等. 一种基于Marx发生器的纳秒脉冲实验平台[J]. 现代应用物理, 2022, 13: 040402Cui Guangxi, Li Junna, Chen Xuliang, et al. A nanosecond pulse experimental platform based on Marx generator[J]. Modern Applied Physics, 2022, 13: 040402) [3] Neuber A A, Chen Y J, Dickens J C, et al. A compact, repetitive, 500kV, 500 J, Marx generator[C]//2005 IEEE Pulsed Power Conference. 2005: 1203-1206. [4] 贾伟, 陈志强, 郭帆, 等. 不同过压耦合机制下Marx发生器建立时延的形成过程分析[J]. 现代应用物理, 2020, 11: 030401Jia Wei, Chen Zhiqiang, Guo Fan, et al. Analysis of the forming process of the Marx-erection time-delay under the different over-voltage coupling mechanism[J]. Modern Applied Physics, 2020, 11: 030401 [5] 杨双, 孙晶晶, 李典耕, 等. 高效率高阻抗层叠Blumlein线固态脉冲发生器研究[J]. 现代应用物理, 2024, 15: 030401Yang Shuang, Sun Jingjing, Li Diangeng, et al. Blumlein lines solid-state pulse generator using high-efficiency and high-resistance stacked[J]. Modern Applied Physics, 2024, 15: 030401 [6] Park S H, Ham Y J, Kim J S, et al. Reliability assessment of mica high voltage capacitor through environmental test and accelerated life test[J]. Journal of the Korean Crystal Growth and Crystal Technology, 2019, 29(6): 270-275. [7] Wang Huai, Blaabjerg F. Reliability of capacitors for DC-link applications in power electronic converters—An overview[J]. IEEE Transactions on Industry Applications, 2014, 50(5): 3569-3578. doi: 10.1109/TIA.2014.2308357 [8] 王振, 肖凯, 张乔木, 等. 基于性能退化的铝电解电容寿命预测方法研究[J]. 电子器件, 2024, 47(5): 1247-1254Wang Zhen, Xiao Kai, Zhang Qiaomu, et al. Research on life prediction of Aluminum electrolytic capacitors based on performance degradation[J]. Chinese Journal of Electron Devices, 2024, 47(5): 1247-1254 [9] Alwitt R, Hills R. The chemistry of failure of aluminum electrolytic capacitors[J]. IEEE Transactions on Parts, Materials and Packaging, 1965, 1(2): 28-34. doi: 10.1109/TPMP.1965.1135396 [10] 李化, 李智威, 王国帅, 等. 脉冲功率应用中的金属化膜电容器寿命预测[J]. 强激光与粒子束, 2014, 26: 045016 doi: 10.3788/HPLPB20142604.45016Li Hua, Li Zhiwei, Wang Guoshuai, et al. Lifetime prediction of metallized polypropylene film capacitors in pulsed power applications[J]. High Power Laser and Particle Beams, 2014, 26: 045016) doi: 10.3788/HPLPB20142604.45016 [11] 李化, 吕霏, 林福昌, 等. 应用于脉冲功率系统的高储能密度电容器[J]. 强激光与粒子束, 2012, 24(3): 554-558 doi: 10.3788/HPLPB20122403.0554Li Hua, Lv Fei, Lin Fuchang, et al. High energy storage density capacitors in pulsed power application[J]. High Power Laser and Particle Beams, 2012, 24(3): 554-558) doi: 10.3788/HPLPB20122403.0554 [12] Liu D, Sampson M J. Some aspects of the failure mechanisms in BaTiO3-Based multilayer ceramic capacitors[C]//Capacitors and Resistors Technology Symposium (CARTS) International. 2012: 59-71. [13] Gill H M, Doney R L, Althoff E K, et al. New aging diagnostics for microdischarge assessment of high dV/dt stressed mica paper capacitors[C]//Conference Record of the the 2002 IEEE International Symposium on Electrical Insulation (Cat. No. 02CH37316). 2002: 327-330. [14] Yao Ran, Li Hui, Lai Wei, et al. Lifetime analysis of metallized polypropylene capacitors in modular multilevel converter based on finite element method[J]. IEEE Journal of Emerging and Selected Topics in Power Electronics, 2021, 9(4): 4248-4259. doi: 10.1109/JESTPE.2020.2981806 [15] Wang Huai, Reigosa P D, Blaabjerg F. A humidity-dependent lifetime derating factor for DC film capacitors[C]//2015 IEEE Energy Conversion Congress and Exposition (ECCE). 2015: 3064-3068. [16] Zhao Jianyin, Liu Fang. Reliability assessment of the metallized film capacitors from degradation data[J]. Microelectronics Reliability, 2007, 47(2/3): 434-436. [17] 许洛源, 欧阳俊, 程振祥, 等. 电介质储能陶瓷的研究进展[J]. 现代技术陶瓷, 2025, 46(3/4): 195-246Xu Luoyuan, Ouyang Jun, Cheng Zhenxiang, et al. A review on the dielectric ceramics for high energy-storage application[J]. Advanced Ceramics, 2025, 46(3/4): 195-246 [18] 董丽杰, 潘萌, 冯锐, 等. 高性能聚合物电介质薄膜研究进展[J]. 长春工业大学学报, 2025, 46(3): 200-206Dong Lijie, Pan Meng, Feng Rui, et al. Progress in high performance polymer dielectric films[J]. Journal of Changchun University of Technology, 2025, 46(3): 200-206 [19] Makdessi M, Sari A, Venet P. Health monitoring of DC link capacitors[J]. Chemical Engineering Transactions, 2013, 33: 1105-1110. [20] Montanari G C, Fabiani D. Searching for the factors which affect self-healing capacitor degradation under non-sinusoidal voltage[J]. IEEE Transactions on Dielectrics and Electrical Insulation, 1999, 6(3): 319-325. doi: 10.1109/94.775617 [21] Montanari G C, Simoni L. Aging phenomenology and modeling[J]. IEEE Transactions on Electrical Insulation, 1993, 28(5): 755-776. doi: 10.1109/14.237740 [22] Smith D L, Savage M E, Ziska G R, et al. ZR Marx capacitor vendor evaluation and lifetime test results[J]. IEEE Transactions on Plasma Science, 2005, 33(4): 1273-1281. doi: 10.1109/TPS.2005.852423 -

下载:

下载: