Metalization and sealing technology of quartz vacuum window film

-

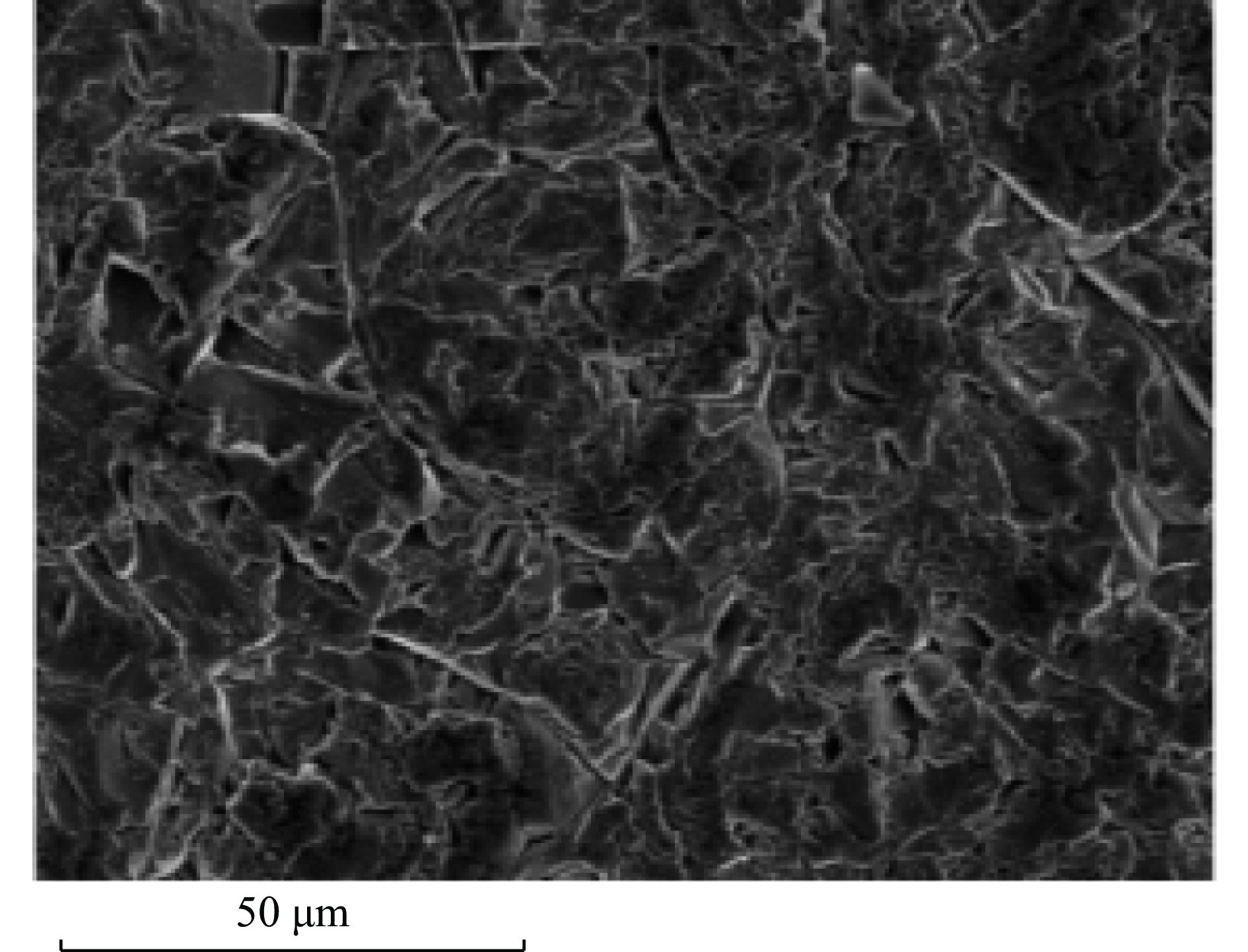

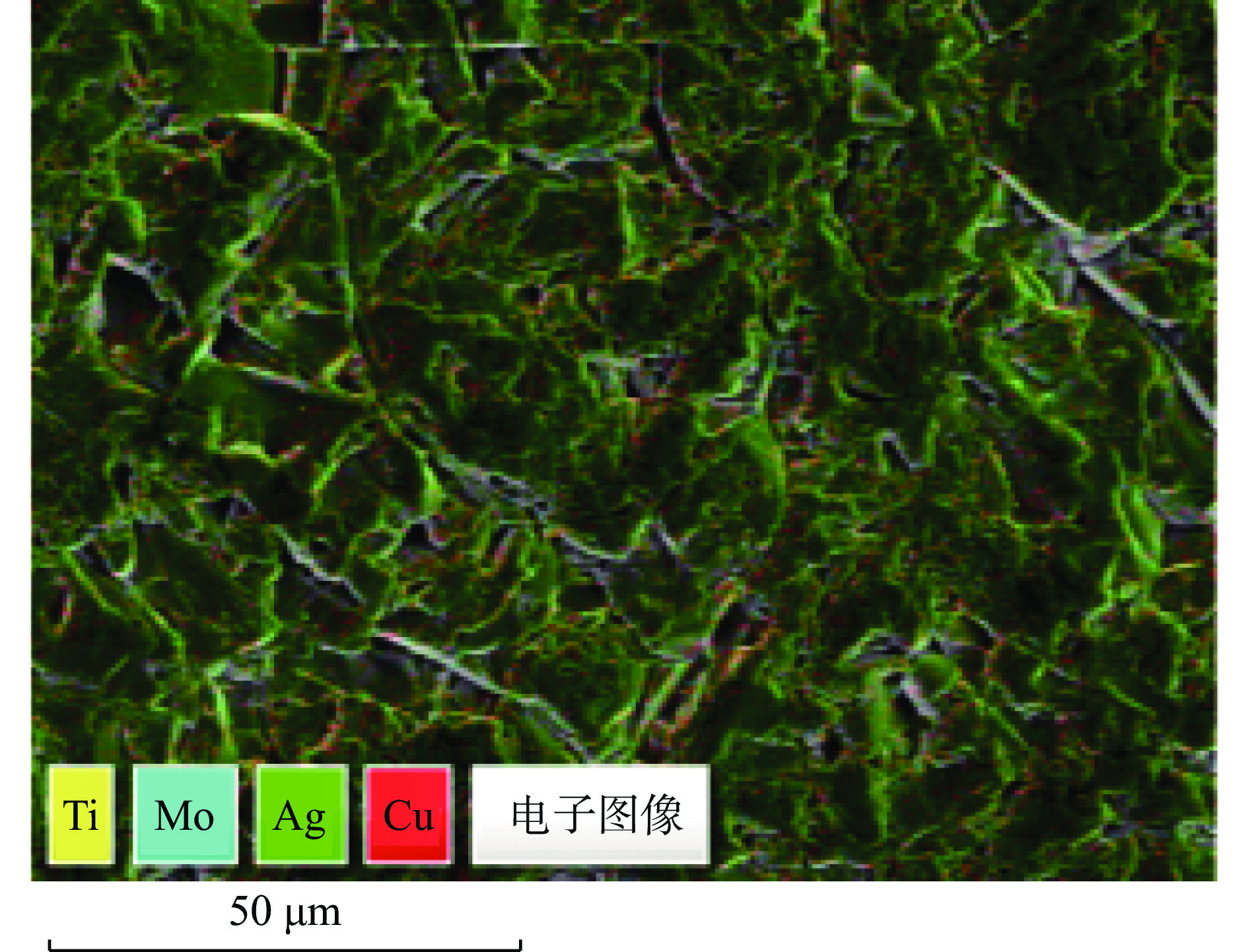

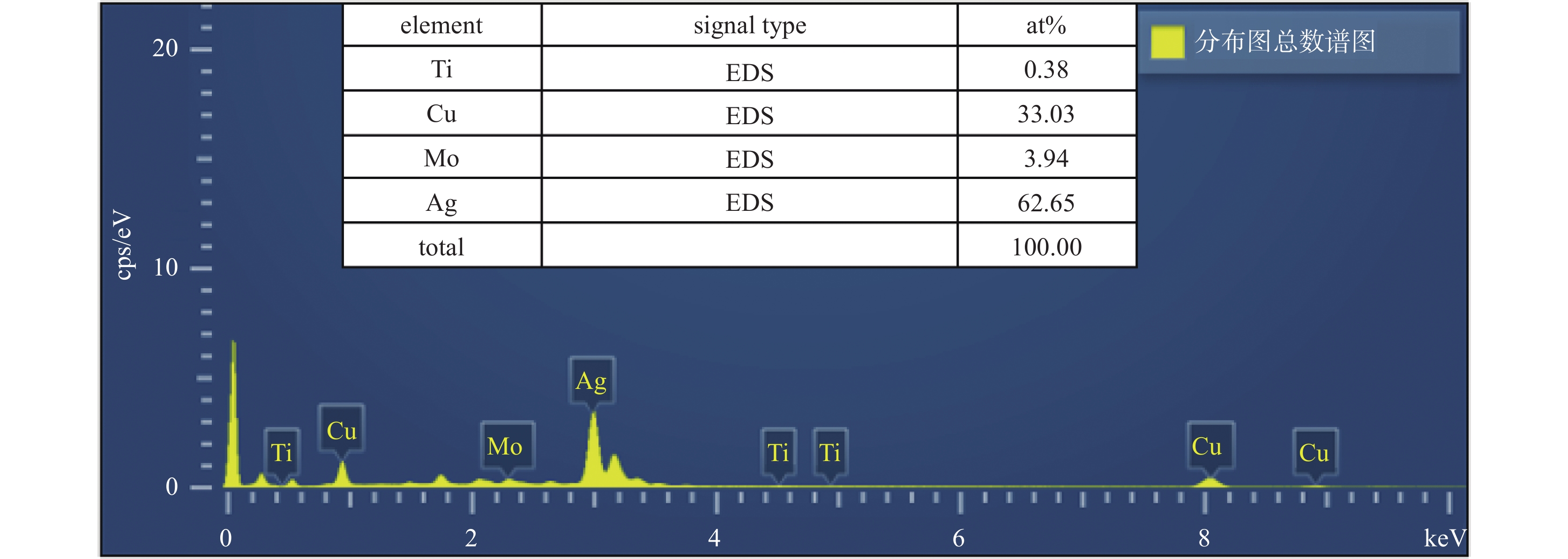

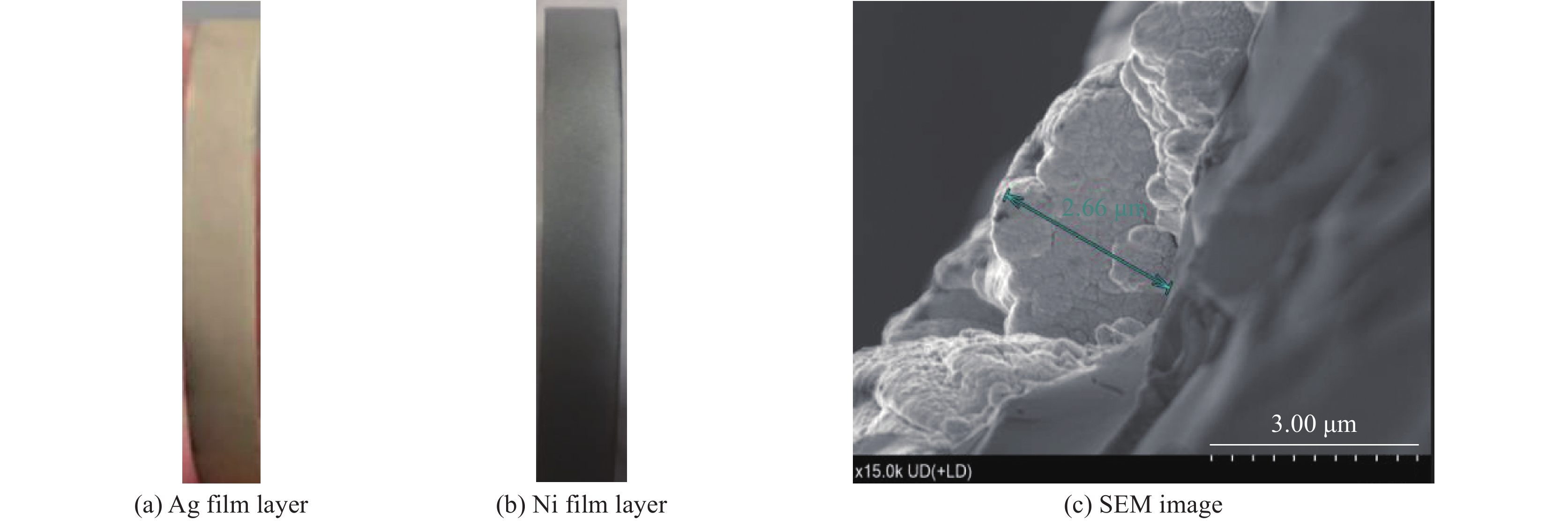

摘要: 面向超高真空精密光学系统的迫切需求,对高性能石英真空窗的封接技术展开系统性研究。石英虽具备优异透光性,但其与金属封接时因热膨胀系数差异较大导致的界面应力集中与真空密封失效,一直是制约低漏率石英真空窗制备的关键技术瓶颈。针对这一难题,提出采用磁控溅射技术在石英焊接面依次沉积Ti/Mo/Cu/Ag多层膜系,构建具有热应力缓冲能力的梯度功能金属化层,实现了石英表面的有效金属化。扫描电镜观察表明,所制备膜层连续致密、结构均匀;纳米压痕实验进一步测得金属化层与石英基底的结合强度约为3.83 N,表明膜层附着牢固可靠。实验结果表明:基于该金属化方案所制备的真空窗口组件,其漏率低于10−12 Pa·L/s。该成果可广泛应用于同步辐射、量子测量及空间探测等领域,为高性能真空器件的发展提供了关键技术支撑。Abstract:

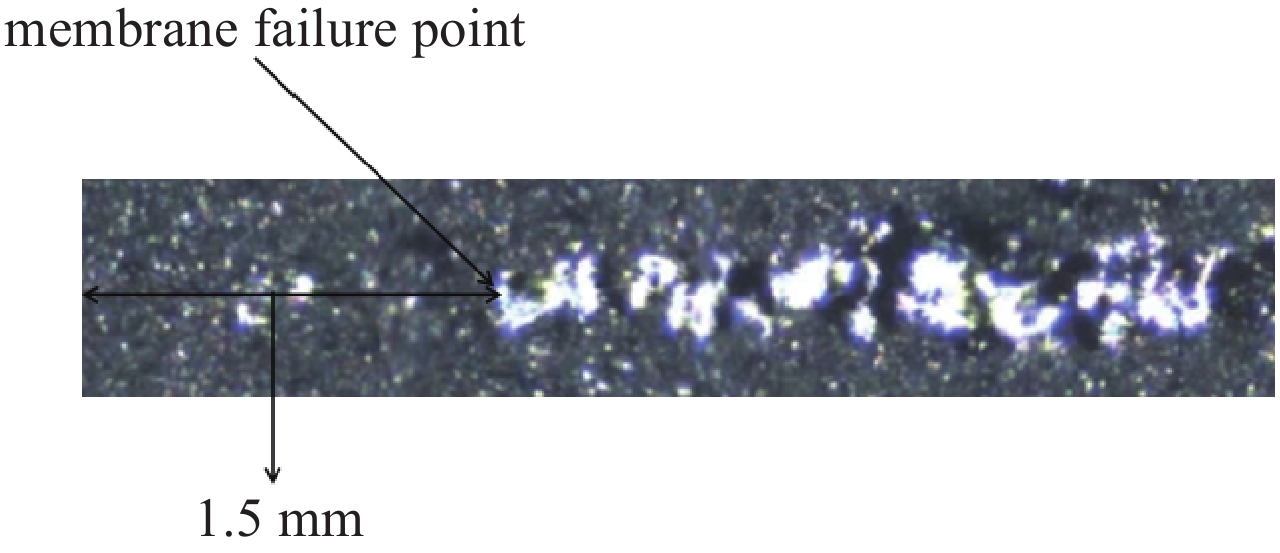

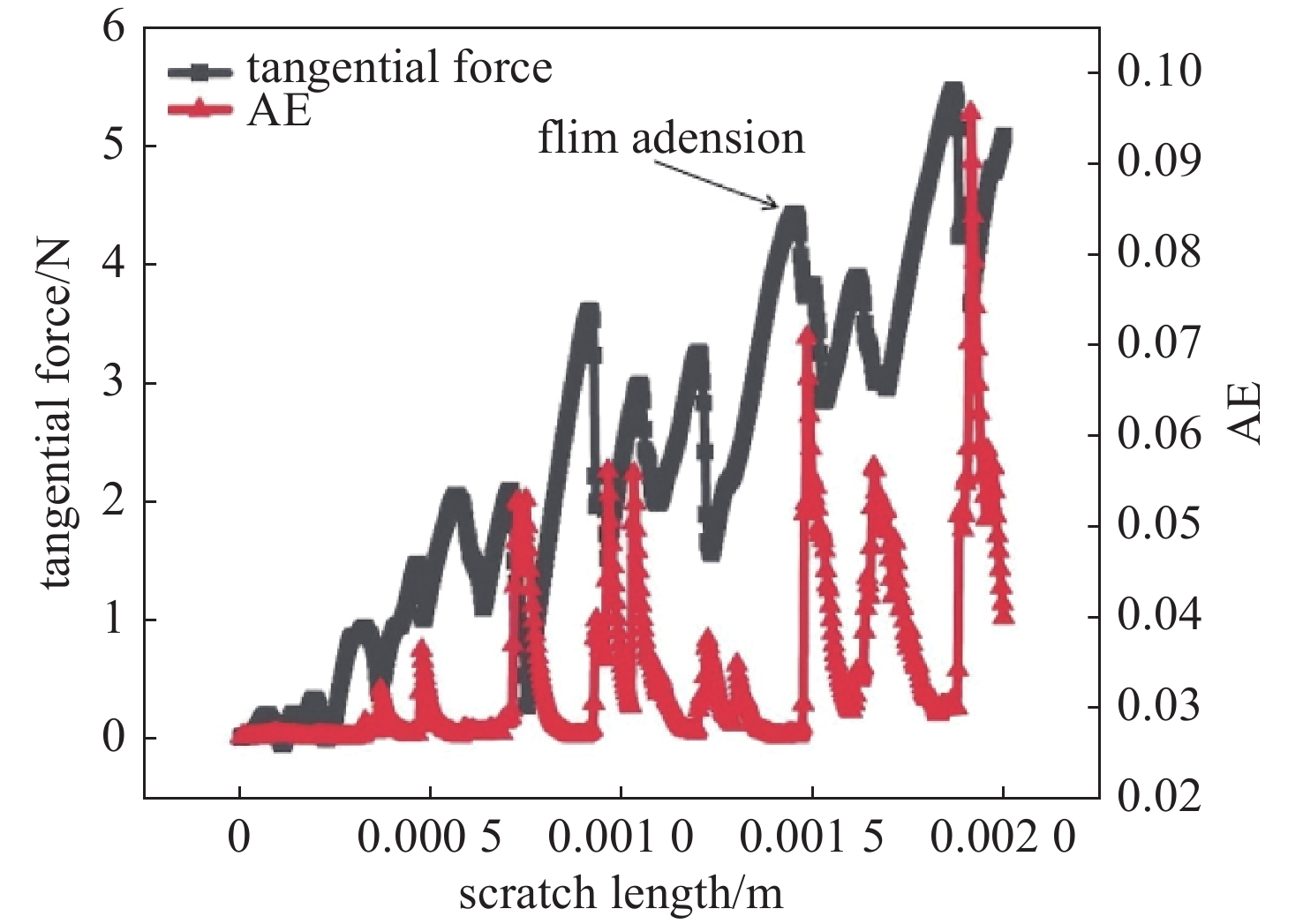

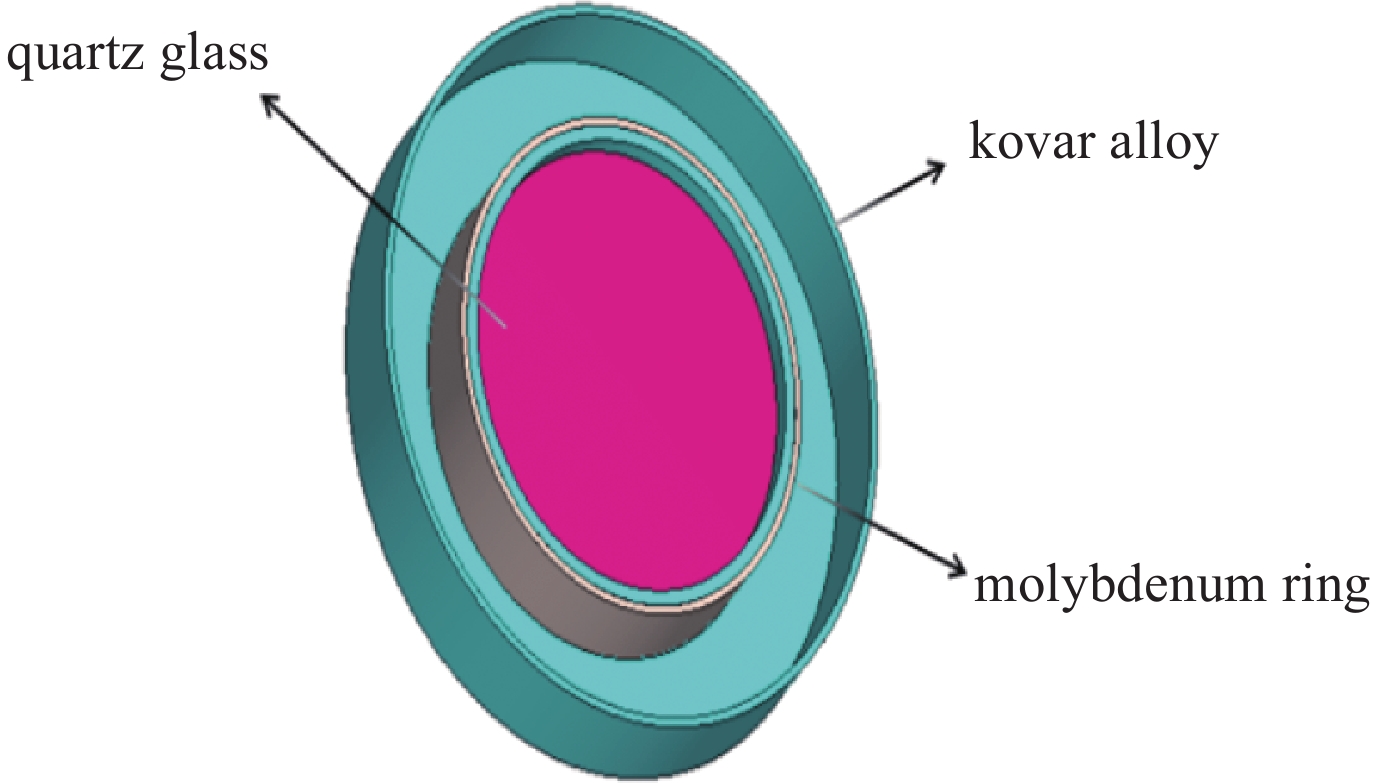

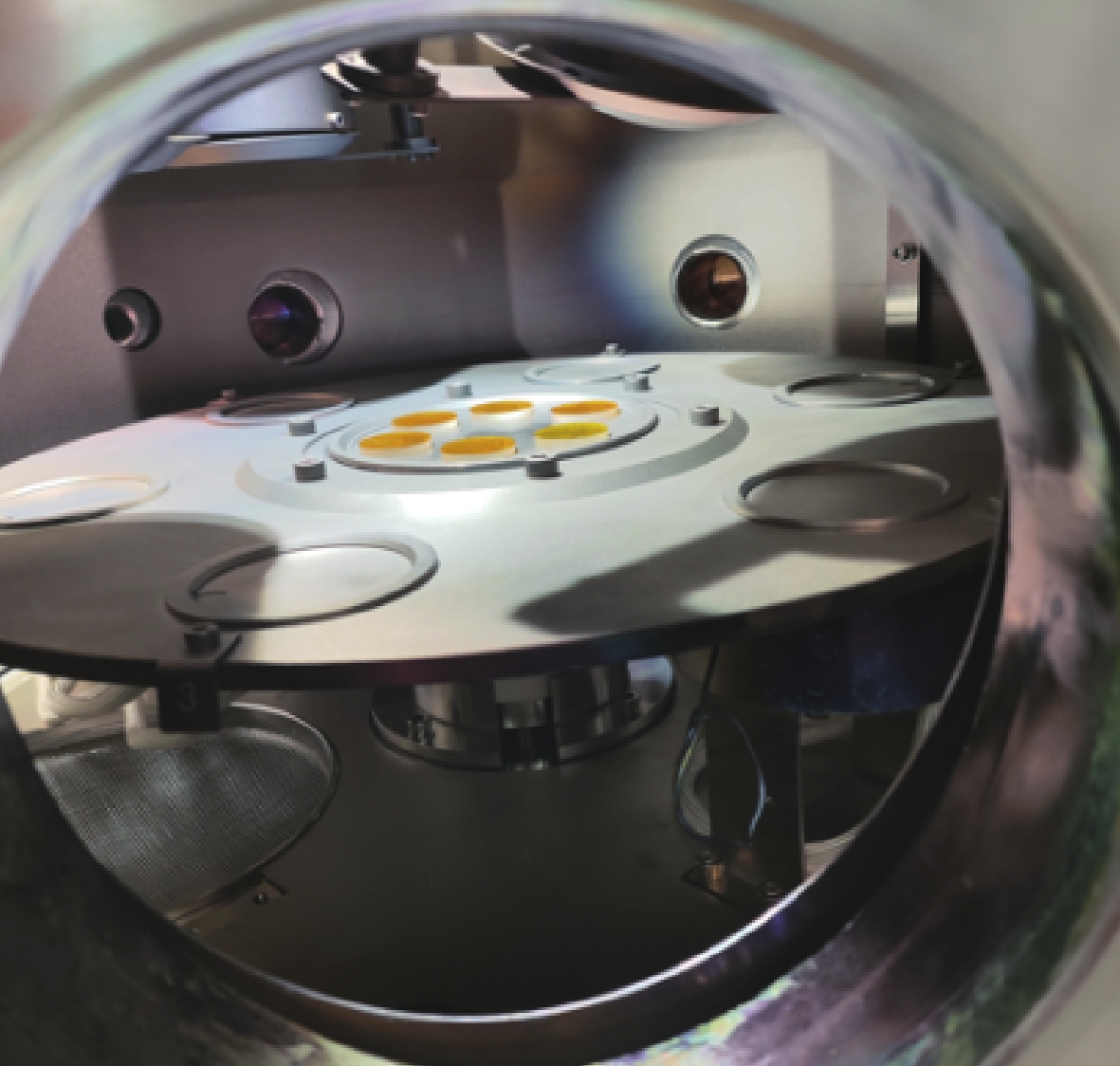

Background Although quartz exhibits excellent light transmittance, the significant difference in thermal expansion coefficients between quartz and metal sealing materials has long been a critical technical bottleneck, leading to interface stress concentration and vacuum sealing failures in low-leakage quartz windows.Purpose This study addresses the urgent demand for ultra-high vacuum precision optical systems by conducting systematic research on sealing technologies for high-performance quartz vacuum windows.Methods To overcome this challenge, this paper innovatively proposes using magnetron sputtering technology to sequentially deposit a Ti/Mo/Cu/Ag multilayer film system on the quartz welding surface, creating a gradient functional metallization layer with thermal stress buffering capability that achieves effective surface metallization..Results Scanning electron microscopy observations revealed continuous, dense, and structurally uniform film layers.Nanoindentation experiments further demonstrated a bonding strength of approximately 3.83N between the metallized layer and quartz substrate, indicating robust adhesion. Experimental results show that vacuum window components fabricated using this metallization scheme achieve leakage rates below 10−12 mbar·L−1.Conclusions This achievement has broad applications in synchrotron radiation, quantum measurement, and space exploration, providing crucial technical support for the development of high-performance vacuum devices.-

Key words:

- quartz glass /

- vacuum brazing /

- magnetron sputtering /

- vacuum window /

- optoelectronic devices

-

表 1 各层材料的物理参数

Table 1. Physical parameters of materials

material hermal

expansivity/℃coefficient of heat

conduction/(W·m−1·K−1)Young modulus/

GPaquartz glass 0.59×10−6 1.8 70 Ti 10.5×10−6 20 70 Mo 5.8×10−6 95 245 Cu 19.5×10−6 90 30 Ag 22.5×10−6 100 15 -

[1] 李志永, 谭荣清, 黄伟, 等. 半导体泵浦铯蒸气实现激光输出[J]. 强激光与粒子束, 2014, 26: 010102 doi: 10.3788/HPLPB201426.010102Li Zhiyong, Tan Rongqing, Huang Wei, et al. Diode pumped cesium vapor laser[J]. High Power Lase and Particle Beams, 2014, 26: 010102 doi: 10.3788/HPLPB201426.010102 [2] 高宇林, 曹磊峰, 周维民, 等. 基于光子筛的软X光谱仪[J]. 强激光与粒子束, 2011, 23(6): 1523-1526 doi: 10.3788/HPLPB20112306.1523Gao Yulin, Cao Leifeng, Zhou Weimin, et al. A soft X-ray spectrograph based on photon sieves[J]. High Power Laser and Particle Beams, 2011, 23(6): 1523-1526 doi: 10.3788/HPLPB20112306.1523 [3] 白婷, 刘晶儒, 叶景峰, 等. 宽波段的类金刚石薄膜光学窗口[J]. 强激光与粒子束, 2006, 18(10): 1629-1633Bai Ting, Liu Jingru, Ye Jingfeng, et al. Development of diamond like carbon film coated window with wide spectral transmission[J]. High Power Laser and Particle Beams, 2006, 18(10): 1629-1633 [4] 荀燕红, 李发. 石英玻璃与金属的预应力封接[C]//第一届陶瓷与金属封接会议论文集. 1990: 69Xun Yanhong, Li Fa. Prestressed sealing of quartz glass and metal[C]//Proceedings of the First Conference on Ceramic-Metal Sealing. 1990: 69 [5] 严增濯. 石英玻璃与金属封接技术进展[J]. 光源与照明, 2005(4): 14-18Yan Zengzhuo. Progress of quartz glass and metalsealing technology[J]. Lamps & Lighting, 2005(4): 14-18 [6] 胡永达. 氮化铝共烧基板金属化及其薄膜金属化特性研究[J]. 电子元件与材料, 2003, 22(2): 50-51 doi: 10.3969/j.issn.1001-2028.2003.02.017Hu Yongda. Study of the character of aluminum nitride co-fire metallization and multilayer thin film metalization[J]. Electronic Components and Materials, 2003, 22(2): 50-51 doi: 10.3969/j.issn.1001-2028.2003.02.017 [7] Rocha L A, Barbosa M A, Puers R. Active metal brazing for joining glass-ceramic to titanium—a study on silver enrichment[J]. Journal of Materials Science: Materials in Medicine, 1995, 6(12): 835-838. doi: 10.1007/BF00134327 [8] 罗磊, 宋立媛, 唐利斌, 等. 晕苯增强CMOS图像传感器[J]. 红外与毫米波学报, 2023, 42(6): 932-937 doi: 10.11972/j.issn.1001-9014.2023.06.027Luo Lei, Song Liyuan, Tang Libin, et al. Coronene enhanced CMOS image sensor[J]. Journal of Infrared and Millimeter Wave, 2023, 42(6): 932-937 doi: 10.11972/j.issn.1001-9014.2023.06.027 [9] 徐嶺茂, 王济洲, 李坤, 等. 蒸发镀膜基片工装改进与镀膜均匀性研究[J]. 真空与低温, 2021, 27(5): 444-448Xu Lingmao, Wang Jizhou, Li Kun, et al. Improvement of substrate holder for evaporation and film uniformity verification[J]. Vacuum & Cryogenics, 2021, 27(5): 444-448 [10] 石英与金属的气密封接——焊封工艺的一些基本要求[J]. 仪表材料, 1972(1): 21-24Gas sealing of quartz and metal —— Some basic requirements of welding sealing process[J]. Instrumentation Materials, 1972(1): 21-24 [11] 王福贞. 磁控溅射镀膜技术新进展[J]. 真空与低温, 2025, 31(5): 543-555 doi: 10.12446/j.issn.1006-7086.2025.05.001Wang Fuzhen. Advances in magnetron sputtering plating technology[J]. Vacuum and Cryogenics, 2025, 31(5): 543-555 doi: 10.12446/j.issn.1006-7086.2025.05.001 [12] 石微, 王晓冬. 新型磁控溅射真空镀膜技术在半导体器件中的应用研究[C]//第十七届国际真空科学与工程应用学术会议摘要集. 2025: 89-90Shi Wei, Wang Xiaodong. Application research of new magnetron sputtering vacuum coating technology in semiconductor devices[C]//Proceedings of the 17th International Conference on Vacuum Science and Engineering Applications. 2025: 89-90 [13] 刘鲁伟, 唐青, 尚吉花, 等. 一种石英玻璃金属化工艺方法: 202510076108.7[P]. 2025-05-16Liu Luwei, Tang Qing, Shang Jihua, et al. Quartz glass metallization process method: 202510076108.7[P]. 2025-05-16 [14] 王建斌. SnAgCu-xTi在石英玻璃和硅表面的润湿行为及界面结构[D]. 兰州: 兰州理工大学, 2020Wang Jianbin. Wetting behavior and interfacial structure of SnAgCu-xTi on silica glass and Si surface[D]. Lanzhou: Lanzhou University of Technology, 2020 [15] 崔新强, 蒋宝财, 郭向朝. 石英玻璃表面金属沉积层的界面研究[J]. 材料保护, 2008, 41(9): 5-7Cui Xinqiang, Jiang Bocai, Guo Xiangchao. Interfacial characteristics of metallic deposited layers on quartz glass used for pulsed xenon lamps[J]. Materials Protection, 2008, 41(9): 5-7 [16] 龚浩, 程东海, 薛行雁, 等. SiO2/TC4钎焊接头的组织性能[J]. 材料热处理学报, 2023, 44(7): 182-188 doi: 10.13289/j.issn.1009-6264.2022-0610Gong Hao, Cheng Donghai, Xue Hangyan, et al. Microstructure and properties of SiO2/TC4 brazed joint[J]. Transactions of Materials and Heat Treatment, 2023, 44(7): 182-188 doi: 10.13289/j.issn.1009-6264.2022-0610 -

下载:

下载: